|

Title: |

1909 Article-Bentel, Margedant & Co., 5 Spindle Car Boring Machine |

|

Source: |

American Engineer & Railroad Journal, V83, Apr 1909, pg. 167 |

|

Insert Date: |

1/15/2016 9:50:20 PM |

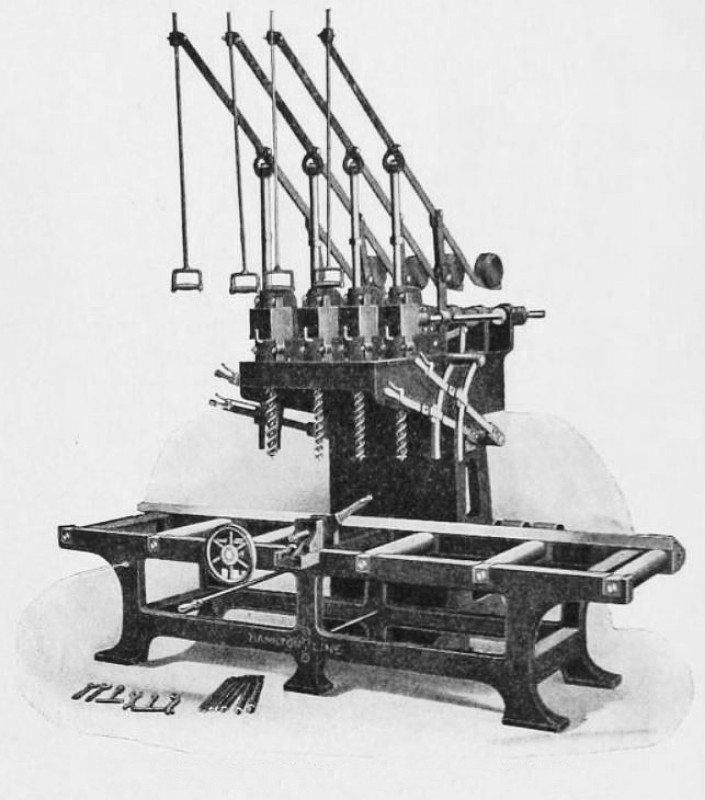

FOUR-SPINDLE VERTICAL CAR BORING MACHINE.

The Hamilton four spindle car boring machine, shown in the illustration, is designed for heavy boring in railroad and car shops and is manufactured by The Bentel-Margedant Company, Hamilton, Ohio. The illustration shows three vertical and two radial Spindles, but these are subject to variation in number.

The spindles, of heavy construction, are mounted in large housings which slide on the frame in in dovetail slides. They have a 20 in. vertical stroke and a transverse adjustment of 22 in., the latter by means of a hand wheel and pinion with chain feed, quick and positive in action. Each spindle is separately driven by its own belt from the rear of the machine and any spindle may be thrown out of commission without disturbing the others. The spindles are provided with a miter gear drive which is covered by a dust-proof box; gears run in long slides preventing wear of the boxes by the action of the spindles. The spindles are brought down separately by hand to do the boring and are returned to their positions by counterbalanced levers in the three vertical spindles and by springs in the radials. Stop gauges are provided to gauge the depth of the hole.

The table is 10 ft. long, clamps 22 in. wide by 16 in. thick and has all the conveniences for handling heavy or light material. The top is provided with six rolls upon which the material rests. The center and two end rolls are geared together by a chain and may be driven either by power or hand feed. A large hand wheel is provided on the center roll for hand adjustment. A center clamp is also used to hold the material against the fence and to prevent the bits from raising it from the table. The power feed for the table consists of reversible friction pulleys controlled from the front by a convenient hand lever. The power feed is generally used for moving long distances, while the hand wheel feed is for accurate setting and short distances. A longer traveling table may be provided, if desired. The countershaft is placed on the floor at the rear of the machine and is provided with tight and loose pulleys. The machine weighs 7,000 lbs., occupies a floor space 6 by 10 ft. and requires from 10 to 15 h. p. for driving. |

|

1909 Bentel, Margedant & Co., 5 Spindle Car Boring Machine

1909 Bentel, Margedant & Co., 5 Spindle Car Boring Machine

|

|