|

Title: |

1908 Article-John B. Morris Machine Tool Co., 18 in. Cone Head Schellenbach Lathe |

|

Source: |

Iron Age, V82, 01 Oct 1908, pg. 915 |

|

Insert Date: |

2/18/2016 9:16:46 PM |

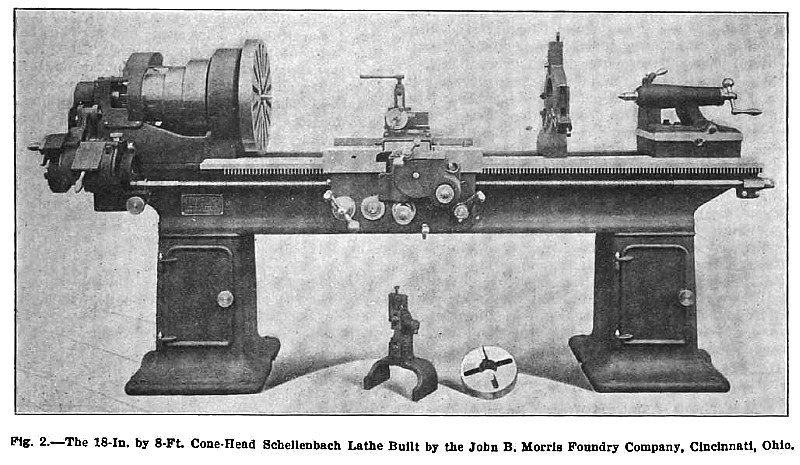

The substitution of a cone-driven head for an all-geared head is the only difference between 18 18-in. x 8 ft. cone-driven Schellenbach engine lathe illustrated in Fig. 2 and the one described in the Iron Age, May 28, 1908. Both are built by the John B. Morris Foundry Company, Cincinnati, Ohio, and are otherwise of the same general design.

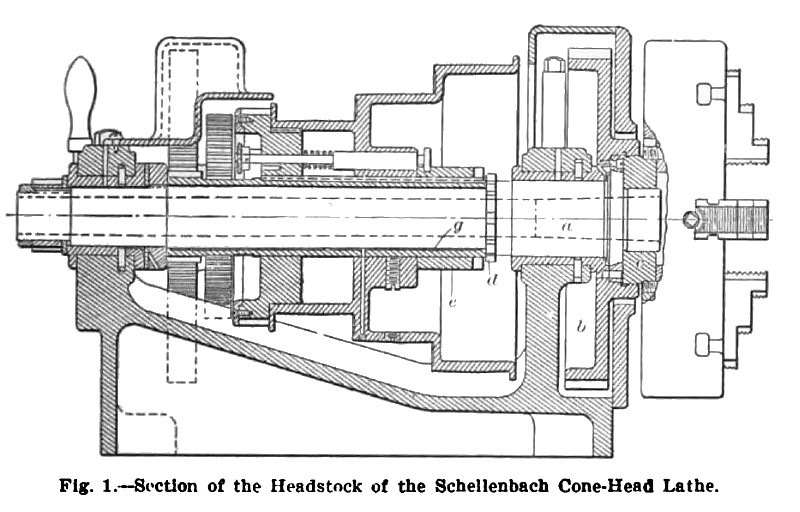

As may be seen from the sectional view of the head-stock, Fig. 1, the drive is direct to the face plate, as in the geared-head machine. The spindle a has a flange at its right end and receives the face gear b, which is doweled and screwed to it. This gear has internal threads and receives the face plates or the chuck. The chuck plate c fits the counterbore of the chuck and is bored to fit the end of the spindle and threaded on the outside to screw into the face gear b. When pressure is exerted against the chuck it clamps the flange of the spindle tightly between the chuck plate c and the face gear b. This eliminates all torsional strains within the spindle when the back gear is in use. The clutch teeth d are formed upon the spindle and engage the clutch e, which is splined to the cone pinion sleeve g. This clutch is operated at the left end of the headstock by a spring-seated plunger which passes through the cone pulley. The plunger has a knurled grip with a detent pin in it for holding the plunger out of engagement. A three-step cone pulley, the largest diameter of which is 12 in., is furnished with this head, and it accommodates a 3-in. double belt. There are two back gear changes, making in all nine changes of speed with a single speed of the countershaft. The countershaft, however, is provided with double friction pulleys, and where a reversing drive is not required it may be driven at two different forward speeds, thus giving the spindle six open-belt speeds and 12 back-gear speeds. The back gear is operated by an eccentric shaft in the ordinary manner. It will be noticed that the overhang of the chuck, from the face of the jaws to the front spindle bearing, is not so great as with the ordinary type of lathe. All of the gearing on the head is enclosed and is of coarse pitch. This machine is provided with a quick change device, giving a thread cutting range of from 2 to 112 to the inch. The lathe has a double plate apron containing a special arrangement for rough chasing threads by the ordinary rack feed in place of the lead screw, the object being to preserve the accuracy of the screw and to use it only for accurate chasing. A single wrench operates all of the adjusting screws on the machine, including those for clamping the tailstock to the shears. The cabinet legs have hinged doors with latches operated by knobs. This lathe is also made in 14 and 16 in. sizes and with a plain System of change gears, as well as with the quick change gears shown. |

|

1908 John B. Morris Machine Tool Co., 18 in. Cone Head Schellenbach Lathe

1908 John B. Morris Machine Tool Co., 18 in. Cone Head Schellenbach Lathe

1908 John B. Morris Machine Tool Co., 18 in. Cone Head Schellenbach Lathe (Headstock)

1908 John B. Morris Machine Tool Co., 18 in. Cone Head Schellenbach Lathe (Headstock)

|

|