|

Title: |

1897 Article-Bentel & Margedant Co., Felly & Rim Planer |

|

Source: |

The Hub, V39, Aug 1897, pg. 305 |

|

Insert Date: |

2/27/2016 5:03:34 PM |

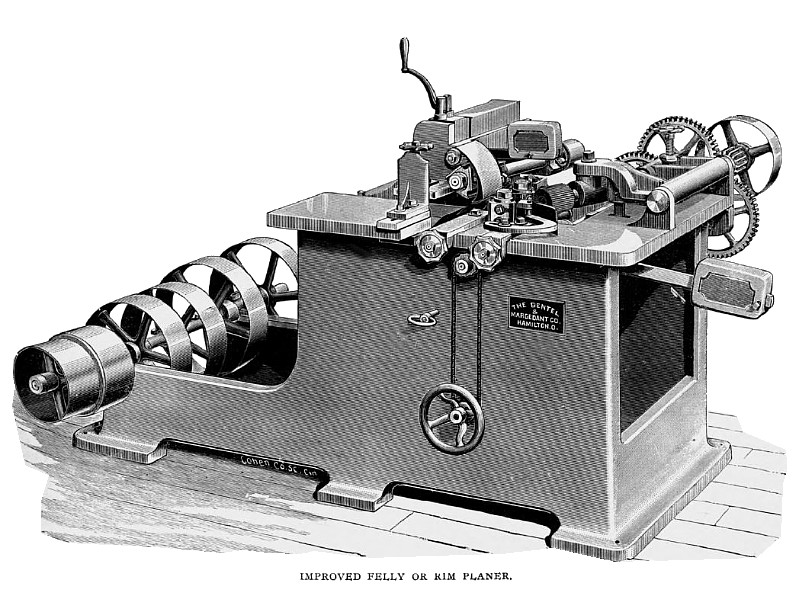

The attention of manufacturers of buggy wheels is called to the newly designed felly planer manufactured by the Bentel & Margedant Co., Hamilton, O., herewith illustrated.

The peculiar requirements of a machine to adapt it to the planing the rims of wheels of various diameters on four sides at one operation, straight or beveling, necessitates a very different construction from required in ordinary planing.

Doing the smoothest and most uniform planing, it feeds continuously and without splintering or gouging the ends of the fellies.

The changes to adapt it to various diameters and thicknesses are y made, while the bevel given the horizontal cutterheads can be accurately retained in the raising and lowering of their housings.

The strongly geared and perfectly parallel feed can be quickly adjusted so that the center line of the feed roll will point directly to the center of any diameter of wheel, of which the felly operated upon forms a part. In other words, it grips the felly in the true radial line of its circle, and feeds it accurately in that line, thus preventing undue friction on the guides, which in other planers of this s' vents the free feeding of the material and causes frequent stopping.

The two horizontal mandrels are long and the mandrel bearings well spread apart. They rest direct on the heavy bracket supports, one only being shown in the cut.

The housings are arranged on a special bed plate, on which they can be set to any required angle or bevel of the felly, in accordance with a scale placed in the bed plate. The bed plate raises and lowers in a true vertical line, by means of a crank and screw on the bracket. It will be seen that the housings thus arranged do not require resetting for bevel or angle but that they retain the given angle for wide or narrow fellies, unless a change in the bevel is desired. The table back of the lower cutterhead is arranged with strong slides on the lower bracket, and can be raised and lowered in accordance with the depth or thickness of cut. The side or vertical cutterhead housings are so arranged that the outside cutterhead planing the inner side of the felly remains fixed, while the inside head planing the tread of the felly, can be adjusted in an instant for thickness. The hand wheel shown in front operates the two screws for sliding the inside mandrel in and out.

This arrangement of the cutterheads requires no readjusting of the guides, as they remain in line with the stationary head.

The machine is provided with adjustable guides, supports, bonnet and springs. Each cutterhead is driven by its own belt, and the shifter for the feed belt is within easy reach of the operator.

The frame of the machine is strong, heavy and well designed, provision being made on the opposite side for the removal of shavings, should they accumulate inside.

The weight of the machine complete is 1,600 pounds.

The countershaft is mounted on the end of the machine frame, as shown, and has tight and loose pulleys of the patent deferential pattern, the loose pulley being of smaller diameter than the tight. The latter is Io in. in diameter by 5¼ in. wide, and should make 1,000 revolutions per minute. |

|

1897 Bentel & Margedant Co., Felly & Rim Planer

1897 Bentel & Margedant Co., Felly & Rim Planer

|

|