|

Title: |

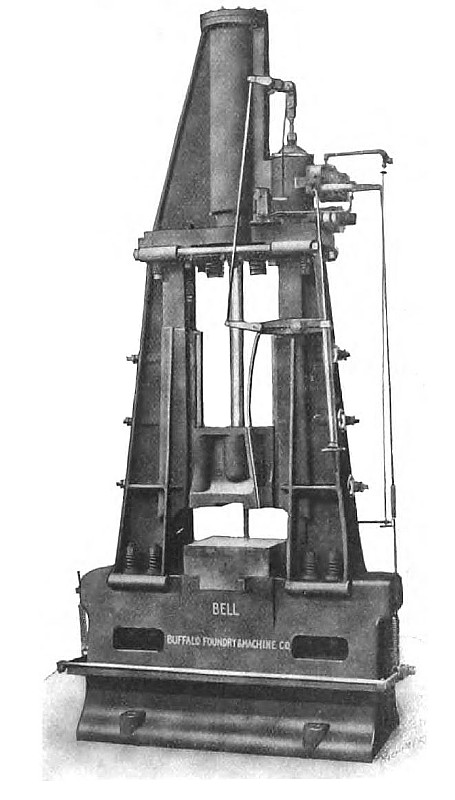

1911 Article-Buffalo Foundry & Machine Co., Bell 1500 lb. Steam Drop Hammer |

|

Source: |

Machinery, V18, Nov 1911, pg. 226 |

|

Insert Date: |

2/2/2017 1:11:46 PM |

The Buffalo Foundry 8: Machine Co., 63 Winchester Ave, Buffalo, N. Y., has designed a new line of steam drop-hammers. A 1500-pound size, having a cylinder 10½, inches in diameter and a stroke of 42 inches, is illustrated herewith. The anvil base of this hammer is an open-hearth steel casting, the weight of which, as compared with the weight of the falling parts, is approximately in the ratio of 20 to 1. The lower die-holder is a hammered steel forging and is secured to the anvil base by a heavy steel tapered key. The frames or columns of the machine are open-hearth steel castings having recesses into which adjustable V-shaped guides are snugly fitted for guiding the hammer head. These guides have a taper gib between them and the column for taking up wear. The hammer head, of vanadium steel, is of ample length. The piston and its rod are made from a solid nickel-chrome vanadium steel forging, having an elastic limit of 85,000 pounds and a tensile strength of 120,000 pounds. This forging is carefully heat-treated before machining. The frames are held at the top by two cross tie-bolts and a steel cap-plate, the outer end of which is gibbed both to the cylinder and the frame. The cylinder is heavily proportioned and strongly ribbed.

The valve motion is of the well-known balanced piston valve type and has a removable sleeve in the piston valve chest. Expansion or stuffing-box joints are provided for the steam and exhaust pipes, and the exhaust pipe is arranged so that no water can remain in the bottom of the steam cylinder. The hammer has an automatic force feed oil pump which forces the oil into the throttle valve chest. This oil pump is operated by the movement of the hammer itself. The throttle valve chest is provided with a by-pass so arranged that after the throttle valve is closed, the by-pass will allow just enough steam to enter the cylinder to hold the hammer head at the top of the stroke; or, if desired, the amount of steam can be increased, in order to keep the hammer operating on a very short stroke at the top. The by-pass can also be closed entirely, thus allowing the hammer to come to rest. The columns are securely attached to the base-plate and to each other, as well as to the cylinder at the top. The distribution of metal throughout the design has been worked out very carefully to enable the hammer to withstand the hard and unusual strains encountered in steam drop-hammer work. |

|

1911 Buffalo Foundry & Machine Co., Bell 1500 lb. Steam Drop Hammer

1911 Buffalo Foundry & Machine Co., Bell 1500 lb. Steam Drop Hammer

|

|