|

Title: |

1911 Article-Kendall & Gent, Break Lathe |

|

Source: |

Machine Tools Commonly Employed In Modern Engineering Workshop, V1, 1911, pg. 39 |

|

Insert Date: |

4/2/2020 9:32:14 PM |

|

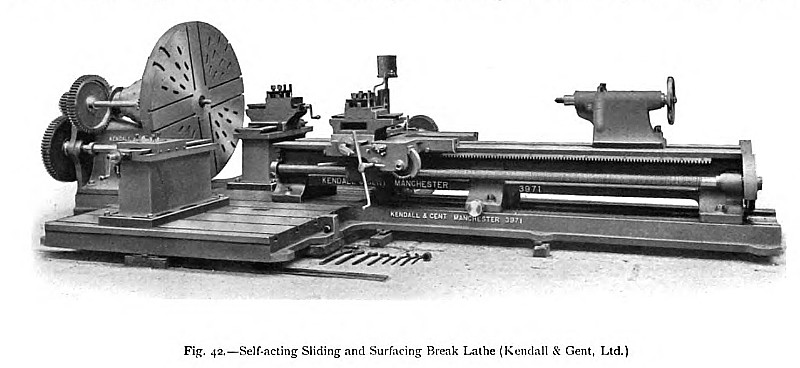

For dealing with a large variety of heavy engineering work a combination of the engine and the surfacing lathes already described is frequently employed. One of these sliding and surfacing break lathes, manufactured by Messrs. Kendall & Gent, Limited, of Manchester, is illustrated in fig. 42, from which it will be seen that the main portions of the machine are mounted upon a large flat foundation plate, the upper surface of which is machined and provided with T grooves cut from the solid casting. Work of 8 ft. diameter can be mounted upon the face plate of the headstock, and the distance between the centres with the break closed is 16 ft. With the break open, the machine will take work of the full diameter—8 ft., extending 6 ft. beyond the face plate. Other similar machines are also made for smaller classes of work. In the example illustrated the headstock is of the cone pulley type, and the arrangement is such that the face-plate can be driven through single, double, or treble gearing. A driving shaft communicates the feed motion to the feed and screw-cutting gears at the extreme end of the bed, which can be moved along the base-plate, towards or from the face-plate, by means of a rack-and -pinion device. Upon the bed is mounted the loose headstock and also the compound slide-rest carriage, which is arranged to swivel, and is provided with a quick hand-traversing rack-and-pinion gear. When screw-cutting the carriage is driven by the large-diameter screw shown at the front of the bed, and the ordinary feed motions are transmitted to the carriage through an independent back shaft. All the necessary feeds and screw-cutting ratios can be obtained in the ordinary manner by the suitable arrangement of change wheels. It should be noted that the inner end of the bed is steadily supported from the base-plate, and that it does not overhang in any position. Two tool-slide standards are adjustably mounted upon the base-plate, and when required the slides are made self-acting by means of quadrants and ratchets. |

|

1911 Kendall & Gent, Break Lathe

1911 Kendall & Gent, Break Lathe

|

|