|

Title: |

1911 Article-Thomas Shanks & Co., Quadruple Geared, Double Bed Break Lathe |

|

Source: |

Machine Tools Commonly Employed In Modern Engineering Workshop, V1, 1911, pgs. 39-40 |

|

Insert Date: |

4/3/2020 1:34:16 PM |

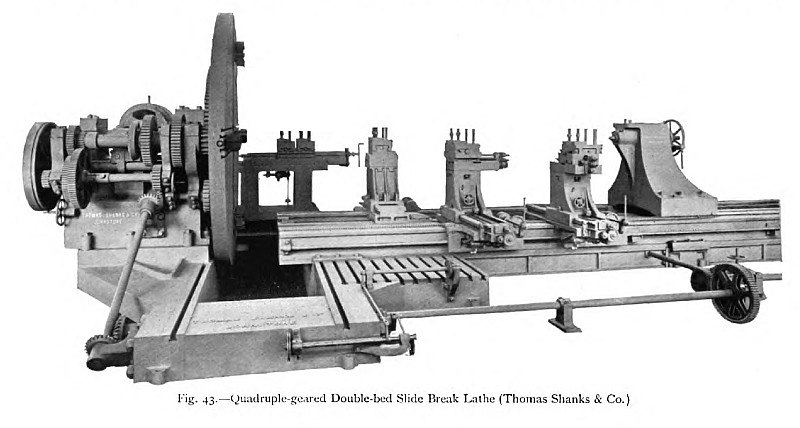

Another lathe of a similar type, but intended for very heavy work, is illustrated in fig. 43. This machine is constructed by Messrs. Thomas Shanks & Co., and it is generally employed when the work is of varied character, and when the quantity of any one kind available is not sufficient to keep a surfacing lathe and a sliding lathe fully occupied. To obtain the required depth of gap, without necessitating the use of tool standards of undesirable height, a gap is provided under the face-plate, and instead of being continuous as in the previous example, the base-plate is built up of four castings, checked and bolted together to form a rigid frame capable of resisting the various strains it may have to bear. This gap arrangement, in the example illustrated, provides a maximum swing in the gap of 25 ft. and a width of 4 ft. Between the centres, when the bed is fully extended, the length is 30 ft., and over the slide bed the swing diameter and the width are 12 ft. and 9 ft. respectively. The fast headstock spindle is a steel forging having a front journal diameter of 15 in. and a width of 21 in. Both journals are carried in gun-metal bearings, and the back journal is provided with a series of thrust rings. If desired the machine can be constructed with a hollow spindle for boring purposes, instead of the solid spindle. Upon the head of the spindle is rigidly fitted and bolted the large -diameter face-plate driven directly by a pinion, which engages with the external machine -cut gear wheel cast in one piece with the plate. Suit able T grooves are machined in the face of the plate to take the four heavy steel jaws provided for holding heavy work, and the four extra steel grips supplied for work of smaller diameter.

Single, treble, and quadruple gears with five reductions are provided, and, in the example illustrated, the head is motor-driven. A cone pulley, driven from an overhead countershaft, can however be substituted for the motor. The double slide bed is a strong casting of ample width planed on the underside to fit the guides of the base-plate, which supports the whole length of the bed. Movement of the bed towards or from the face-plate is effected by power, as the weight is too great for any sufficiently rapid hand gear. Each of the two slides is provided with one or more power-driven carriages provided with long disengaging nuts. For sliding and boring, the front and back saddles are independently driven through guide screws and change-wheel systems, which give two or three feed changes, and enable the feed to be reversed without altering the swing frame. Each saddle at the front has a self- acting surfacing rest and swivel rest; the insetting slide being operated by hand, while on the other hand each of the back saddles has a self-acting surfacing rest and fixed compound rest specially designed to resist upward forces. Behind the machine in the illustration is shown an independent bed fitted with a telescopic slide and two in-cutting tool rests. This bed, which has been removed for clearness of illustration, is mounted at the front of the base-plate for surfacing work in the gap. |

|

1911 Thomas Shanks & Co., Quadruple Geared, Double Bed Break Lathe

1911 Thomas Shanks & Co., Quadruple Geared, Double Bed Break Lathe

|

|