|

Title: |

1911 Article-Alfred Herbert Ltd., Single Spindle Vertical Drill Press |

|

Source: |

Machine Tools Commonly Employed In Modern Engineering Workshop, V2, 1911, pg. 4 |

|

Insert Date: |

4/8/2020 2:02:40 PM |

|

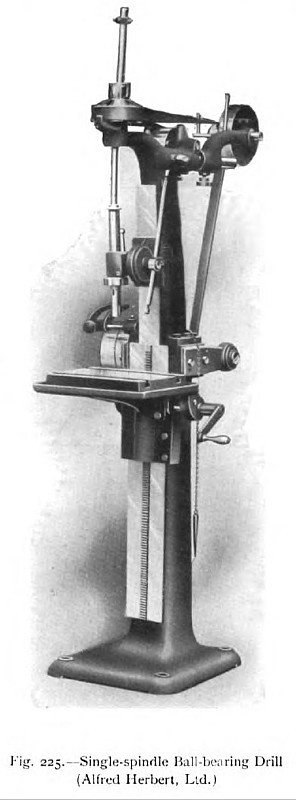

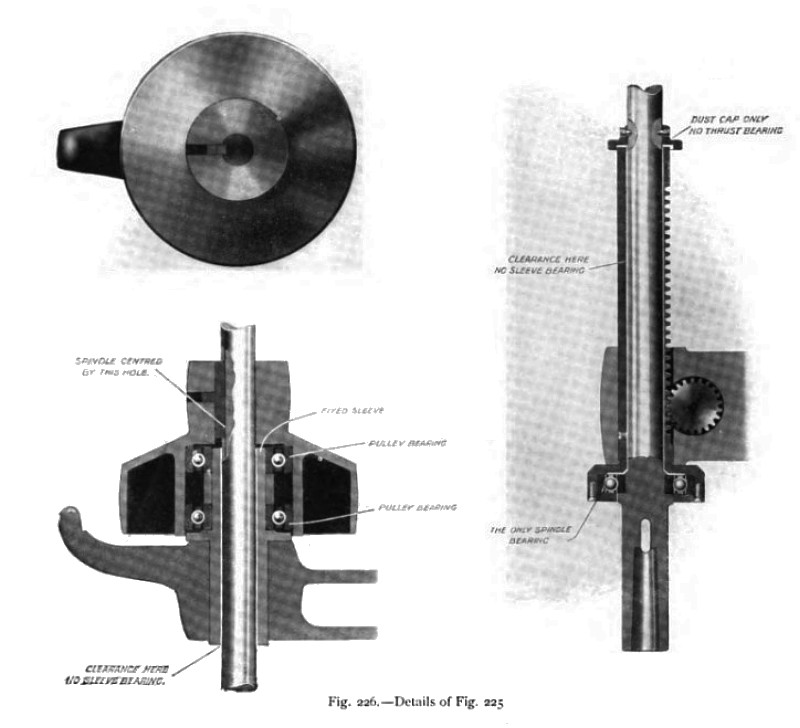

In fig. 225 is illustrated a single-spindle machine, manufactured by Alfred Herbert, Ltd., and fitted with single- track ball bearings. Machines of the same type are also constructed with two, three, four, or more spindles if required. A section through the spindle and its bearings is given in fig. 226, which shows the single-track ball bearings referred to above. In the illustration the spindle is broken for convenience of reproduction, the movable lower spindle bearing being shown at the right side. It will be seen that the spindle has no direct connection with the feed sleeve, within which it runs upon the ball bearing shown. The sleeve is fed by a rack-and-pinion gear, the hand lever being adjustable to suit the sensitiveness of the adjustment or the travel desired, and a flat helical spring is provided to balance the spindle. At the upper end the spindle is centred within the top pulley of the driving cone, which is mounted upon ball bearings on the fixed sleeve, shown in the illustration. By this arrangement the pull of the driving belt acts almost entirely on the fixed sleeve, and exerts no bending force on the spindle, which therefore does not tend to wear out of alignment. A key in the pulley head engages a keyway cut in the spindle, to which the drive is thus communicated. The projecting nose of the upper bearing serves to support the belt when, for any reason, it leaves the driving pulley. Four drilling speeds are available, and in the case of multiple - spindle machines each spindle has its own driving gear and can therefore be driven at any one of the speeds independently of the others. One of the spindles of multiple machines is generally provided with two extra slow speeds suitable for tapping, facing, and counterboring operations. The spindle pulley is a two-step cone, driven by a long endless belt from a corresponding cone on the countershaft. This counter-shaft cone can be adjusted in position along the shaft, to suit the location of the driving belt; and one or other of the cone steps and the idler pulleys, mounted on the projecting arm at the back of the machine, can be adjusted vertically so as to guide the belt on to the upper or the lower step of the spindle cone. No delicate adjustment of these pulleys is required to make the long driving belt run correctly. |

|

1911 Alfred Herbert Ltd., Single Spindle Vertical Drill Press

1911 Alfred Herbert Ltd., Single Spindle Vertical Drill Press

1911 Alfred Herbert Ltd., Single Spindle Vertical Drill Press (Details)

1911 Alfred Herbert Ltd., Single Spindle Vertical Drill Press (Details)

|

|