|

Title: |

1911 Article-Kendall & Gent, Ltd., Adjustable Radial Drilling & Tapping Machine |

|

Source: |

Machine Tools Commonly Employed In Modern Engineering Workshop, V2, 1911, pgs. 25-28 |

|

Insert Date: |

4/25/2020 9:38:46 PM |

|

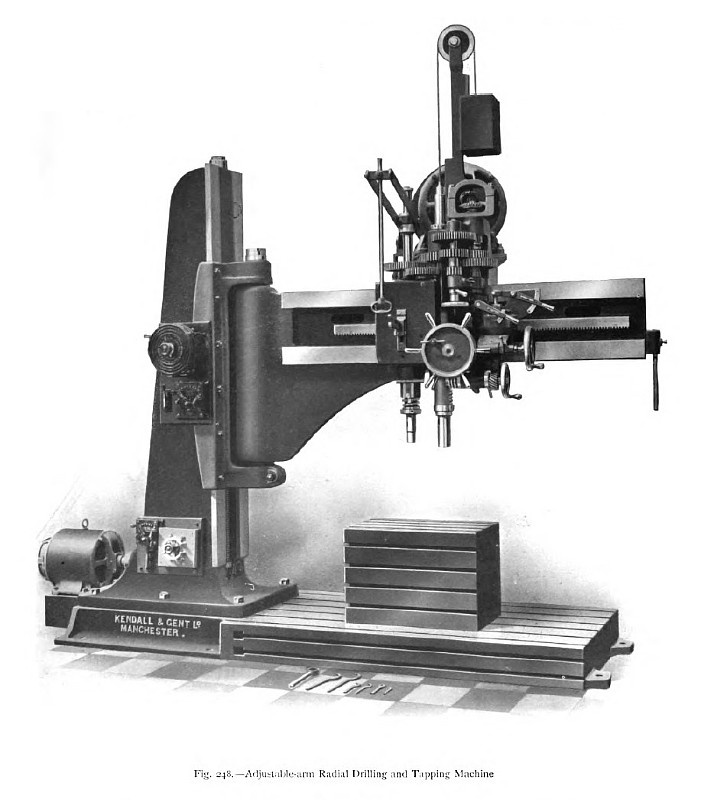

In the previous machines the vertical adjustment of the spindle is limited to the feed motion, and it is therefore necessary to raise the work to the required height, either by elevating the table when such an arrangement is provided, or by the use of blocks. In the machine illustrated in fig. 248, which is one built by Kendall & Gent, Limited, the radial arm is mounted upon a saddle, which can be moved vertically through a distance of 30 in. along the machined face of the heavy box section column of the machine. It is raised and lowered by an independent reversible motor, the starting and regulating switches of which are situated near the motor at the foot of the column. To relieve the motor of unnecessary load the weight of the arm is counterbalanced. Clamps are provided for rigidly locking the arm in any adjusted position. On the saddle there are mounted two spindles, one driven at speeds suitable for high-speed drilling, and the other at a low speed for slow drilling and tapping operations. The latter spindle is geared down relatively to the drilling spindle in the ratio of about 3 or 4 to 1, and it is provided with the usual reversing motion for quickly withdrawing the tap at a speed about three times that of the tapping speed. An arrangement is also provided for automatically stopping the motion when the tap reaches the bottom of the hole, or when the driving force exceeds a safe limit, as, for example, when the hole is of too small a diameter. In this way the danger of breaking the tap is largely avoided, and studs can also be screwed firmly home without risk of damage. When the hole has been drilled the tapping spindle is brought exactly over it by a single movement of the handwheel, thus ensuring the greatest accuracy without any special setting. Important advantages result from the use of a separate tapping spindle driven from the drilling spindle at a lower speed. When drilling and tapping a number of holes in succession, the work can be carried on continuously without stopping the machine to replace the drill or tap and without altering the speed. The tap runs at the correct speed proportional to that of the drill, and as the latter always runs in the same direction, and does not therefore require to be frequently reversed, the wear is less and the alignment can be better maintained. The drilling spindle, as well as the tapping spindle, is balanced to facilitate its rapid movement. It is provided with hand and also variable self-acting feed motion by steel rack-and-pinion and tangent gearing, so arranged that the handwheels for the quick and slow motions, and the handle for putting the self-acting feed in and out of gear, arc conveniently situated at the bottom of the saddle within easy reach of the operator. Any one of the three self-acting feed rates can be applied while the spindle is running; and although no friction or tooth clutches are used, the putting in or out of the power feed, connecting the hand, feed, or entirely releasing the worm wheel so as to leave the spindle free, are accomplished by the movement of one lever. The spindle driving gear is driven by a variable-speed motor carried on the saddle, and in addition to the ordinary single gear there are provided two ratios of treble gearing. The motor starting and regulating switches are mounted upon a panel attached to the side of the arm carriage. |

|

1911 Kendall & Gent, Ltd., Adjustable Radial Drilling & Tapping Machine

1911 Kendall & Gent, Ltd., Adjustable Radial Drilling & Tapping Machine

|

|