|

Title: |

1911 Article-Alfred Herbert, Ltd., Conventry Concentric Lathe Chuck |

|

Source: |

Machine Tools Commonly Employed In Modern Engineering Workshop, V1, 1911, pg. 52 |

|

Insert Date: |

5/5/2020 1:28:40 PM |

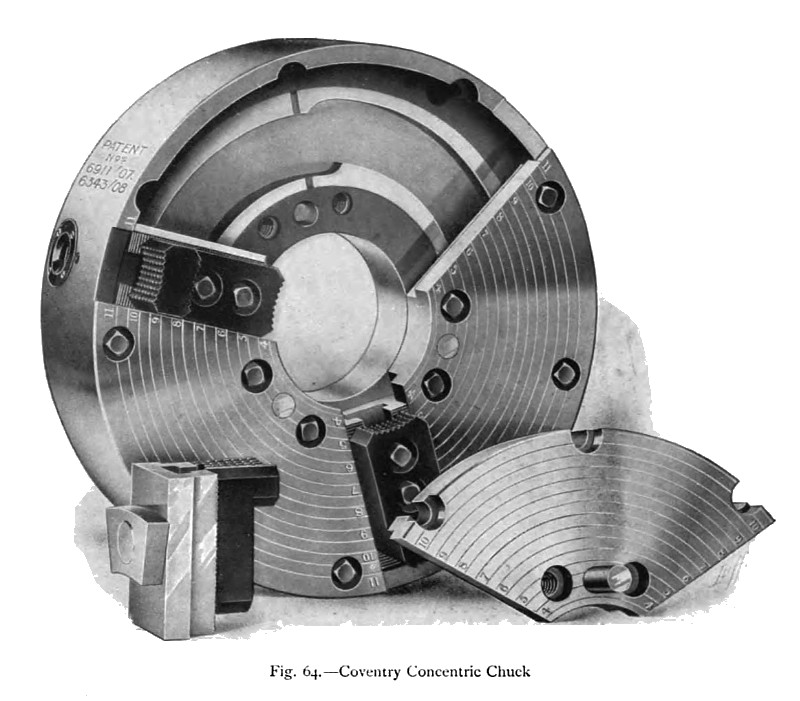

Fig. 64 represents the partially dismantled "Coventry" concentric chuck, manufactured by Messrs. Alfred Herbert, Ltd. This universal chuck embodies certain interesting features, which have been devised to overcome some of the many well-known defects of ordinary scroll chucks. Each jaw consists of a lower slide guided in a radial slot, and of a gripping jaw adjustable along a T guiding slot in the upper surface of the lower slide. To the underside of each slide is pivoted a block, which engages in one of three eccentric grooves in the face of a rotatable scroll plate. Three radially disposed pinions, operated from the periphery of the chuck body, mesh with a crown wheel on the rim of the scroll and serve to rotate it, and thus to move the jaws, by equal amounts, towards or from the centre. It will be seen that, when desired, the jaws may be independently adjusted upon the jaw slides, or be readily reversed, or replaced by others. Spiral scrolls of the ordinary types are a source of frequent trouble, owing to the smallness of the contact surfaces of the sliding blocks. Since the curvature of a spiral necessarily changes, it is only possible to make the sliding blocks fit the grooves over short surfaces of contact; and as a result, undue wear and backlash of the jaws soon occur. In the Coventry arrangement the scroll plate has three eccentric grooves, each of which is of circular and not spiral form. Long sliding blocks, having large wearing surfaces, can thus be made to fit the grooves accurately, and any tendency of the chuck to become untrue is thus greatly reduced. The body of the chuck is in one piece, and the face consists of three sector plates, which retain the scroll and pinion shafts in position, and which also form at their edges the accurately formed guides within which the jaw slides work. These sector plates are secured to the chuck body by hardened-steel square-headed collar screws, which take all the outward bursting pressure at the chuck face. Radial movement is prevented by the chuck body, against which the edge of each sector is butted, and angular movement is prevented by large dowel pins. It will be seen that the internal portions are completely enclosed, and that the scroll is not exposed at any position. Metal cuttings can- not, therefore, gain entrance to the working parts, and the truth of the chuck can thus be better maintained; more especially owing to the fact, that the internal parts can be kept clean and well lubricated. Numerous other devices have been adopted for simultaneously operating the jaws of chucks; but few of the arrangements in common use can be considered satisfactory in all respects. In many cases the working parts are too numerous and small; but frequently the failure of certain forms of chucks is due to the insufficient strength of the body or case, and the softness of the materials used.

GB Patent: GB-190,706,911

http://datamp.org/patents/displayPatent.php?id=65435

GB Patent: GB-190,806,343

http://datamp.org/patents/displayPatent.php?pn=190806343&id=65437 |

|

1911 Alfred Herbert, Ltd., Conventry Concentric Lathe Chuck

1911 Alfred Herbert, Ltd., Conventry Concentric Lathe Chuck

|

|