|

Title: |

1911 Article-Warner & Swasey Co.,Turret Screw Machine |

|

Source: |

Machine Tools Commonly Employed In Modern Engineering Workshop, V1, 1911, pg. 59 |

|

Insert Date: |

7/25/2020 9:47:47 PM |

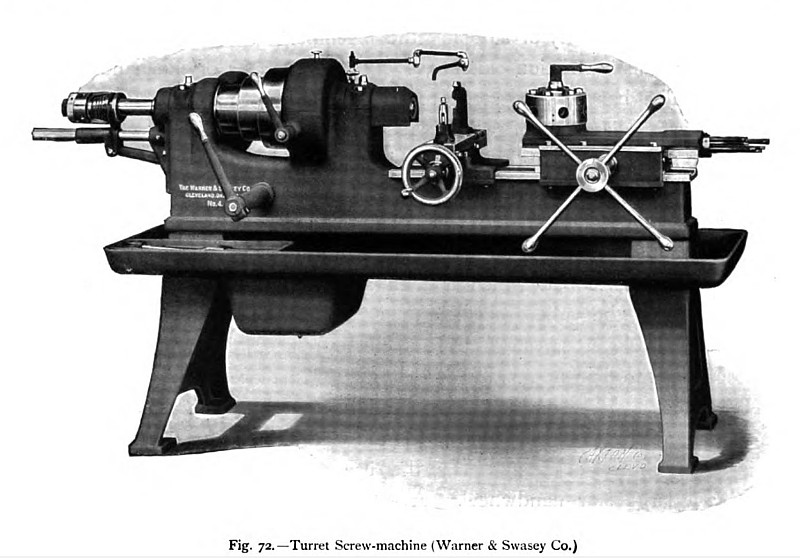

In fig. 72 is illustrated a simple type of turret screw- machine manufactured by the Warner & Swasey Company, of America. This particular machine is intended for the manufacture of screws, studs, bolts, and similar pieces from bar stock, fed through the hollow spindle; but, in the larger sizes of the same type of machine, the nose of the spindle is screwed to take a chuck, and the machine is therefore adapted for operating on chucked work. The head and bed are cast in one piece to obtain the greatest possible strength and rigidity; and the enclosed box section of the bed itself ensures the maximum torsional rigidity. It is supported at the ends upon blocks, which prevent distortion, and is provided with a large oil pan, to collect all the metal cuttings and also the oil with which the work is lubricated. Beneath the pan there is a well, into which the oil drains through a strainer, and from this well the oil is drawn and returned to the cutting tool, by means of a geared pump, which acts in either direction. In the example shown, the coned head has three steps providing three speeds of 450, 277, and 174 revolutions per minute, when the counter shaft is run at 255 revolutions, and, in addition, the back gears, which have a ratio of 5 to 1, provide a further series of three slower speeds, namely 91, 56, and 35. It will be seen that these speeds form a series, increasing approximately in geometrical progression, the ratio being about 1.7. Corresponding with each step of the cone there are thus two spindle speeds, one suitable for turning, and the other for threading heavy work or for turning different diameters on the same piece.

To facilitate the rapid changing from the open belt to the corresponding slow speeds, without the necessity of stopping the machine, the back gears are engaged and disengaged by means of friction clutches, operated by means of the handle at the front of the head. The bar or wire stock to be operated upon is fed through the hollow spindle, the inside diameter of which is 1-3/4 in.; but the capacity of the automatic chuck fitted on the nose of the spindle is 1-3/8 in. The automatic chuck and wire feed arrangements provided enable the operator, by the movement of one lever, to feed, grip, and release the stock bar being operated upon while the machine is running. When this lever is moved forwards, the automatic chuck opens and releases its grip upon the stock bar, which is then advanced by the movement of the lever until it encounters the adjustable length stop inserted in the turret. When the lever is moved backwards, the wire feed clutch releases its grip, and the automatic chuck closes on the bar and holds it securely. Increased leverage is obtained for closing the chuck, with the necessary force, by operating the chuck through a link mechanism connected to the lever. |

|

1911 Warner & Swasey Co.,Turret Screw Machine

1911 Warner & Swasey Co.,Turret Screw Machine

|

|