|

Title: |

1911 Article-Alfred Herbert, Ltd., #9 Capstan Lathe |

|

Source: |

Machine Tools Commonly Employed In Modern Engineering Workshop, V1, 1911, pgs. 66-67 |

|

Insert Date: |

7/31/2020 1:27:54 PM |

|

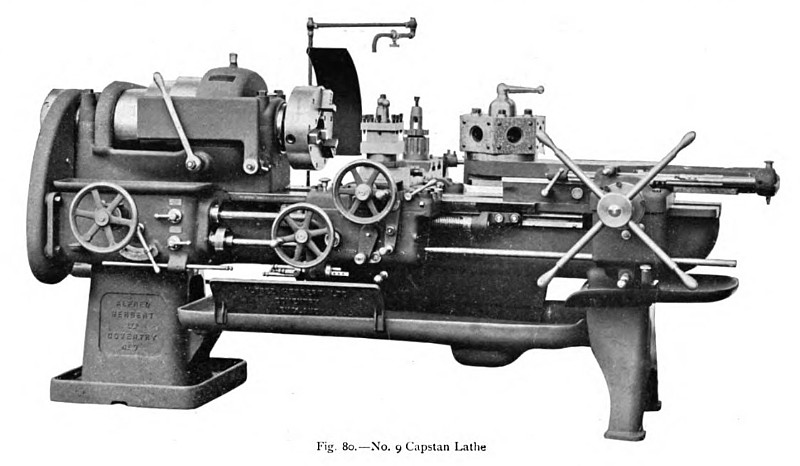

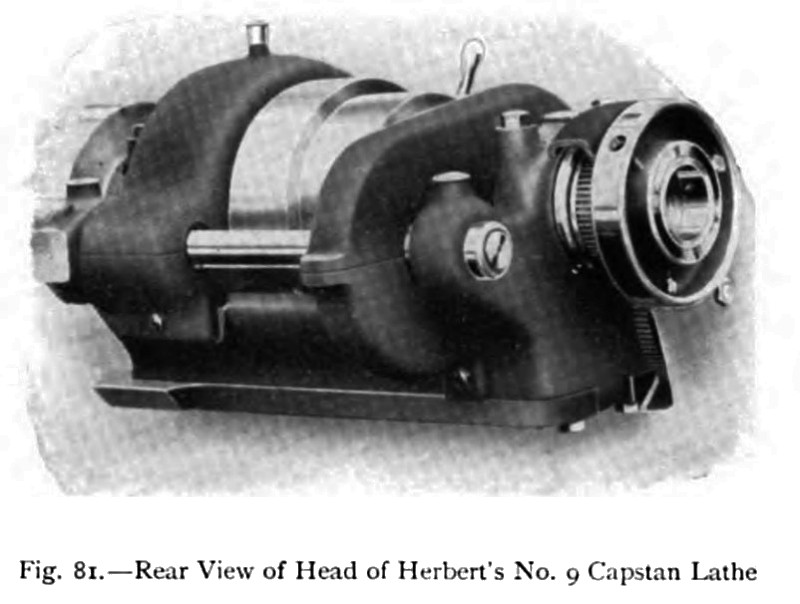

The No. 9 capstan lathe, which is manufactured by Messrs. Alfred Herbert, Limited, of Coventry, is illustrated in fig. 80 on the following page. This particular size of capstan lathe is capable of dealing with rod of three and a half inches diameter and also with chuck work, the maximum swing being 18 in. over the bed and about 10 in. over the cross slide. Although the machine indicated has a cone headstock, a similar type is provided with a head of the all-geared single-pulley drive design when the nature of the work necessitates a larger range of spindle speeds and a greater power. With the cone drive and back-gearing the number of forward speeds is 12 and the reverse speeds 6, whereas with the all-geared head there are available 16 forward and 16 reverse speeds, the total range being amply sufficient for all the requirements of high-speed steel cutting tools. In fig. 81 the cone pulley headstock is separately illustrated, the view being from the rear end of the hollow spindle. The nose of the spindle is flanged to take the chuck directly without any intermediate faceplate, and in this way the overhang of the work is reduced to the minimum amount. A ball-thrust bearing is provided to take the thrust of the cut and reduce the stresses on the gearing, which, in the case of all-geared heads, is a feature of some importance. Gun-metal spindle bearings, tinned and lined with antifriction white metal, are fitted, and the bearings are lubricated by continuous siphon oilers. While the machine is running the back gearing can be inserted or the motion of the spindle reversed by means of friction clutches operated by a lever, indicated at the front of the general view. These friction clutches are of sufficient size to transmit the full power of the head, and provision is made for their adjustment. |

|

1911 Alfred Herbert, Ltd., #9 Capstan Lathe

1911 Alfred Herbert, Ltd., #9 Capstan Lathe

1911 Alfred Herbert, Ltd., #9 Capstan Lathe (Rear View of Headstock

1911 Alfred Herbert, Ltd., #9 Capstan Lathe (Rear View of Headstock

|

|