|

Title: |

1911 Article-Jones & Lamson Machine Co., New Flat Turret Lathe |

|

Source: |

Machine Tools Commonly Employed In Modern Engineering Workshop, V1, 1911, pg. 80 |

|

Insert Date: |

4/16/2022 8:33:18 PM |

The Hartness Flat Turret Lathe— In all the machines hitherto described, whether of the engine lathe or the screw - machine turret types, surfacing operations have been performed by suitably feeding the tool transversely across the work. Thus, in the case of the engine lathe, the surfacing tool is mounted upon a cross slide on the main carriage, and in the turret lathe upon a separate tool-post cross slide; the main carriage being devoted solely to the support of the turret. To the use of cross- slide arrangements there is the objection, that the number of parts between the supporting surface of the bed and the tool increases the difficulty of holding the tool rigidly, and consequently affects the accuracy and finish of the work.

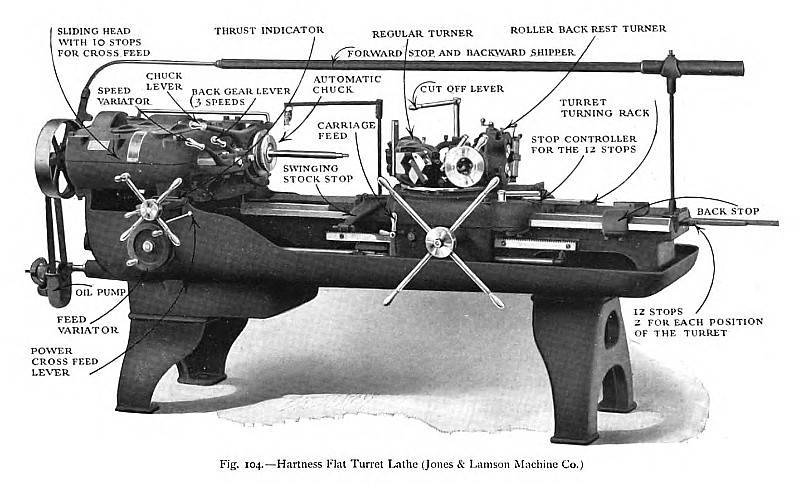

In the Hartness flat-turret lathe, manufactured by the Jones & Lamson Machine Company, of America, and illustrated in fig. 104, the use of the cross slide is dispensed with, and the work itself is traversed across the tool, which remains fixed in the turret. Between the tool and the bed of the machine there are therefore the fewest parts and the smallest distance; that is, there is only the necessary mechanism of the turret and its carriage. Surfacing operations are performed, as already stated, by traversing the whole head of the machine, which is suitably mounted upon cross shears; and, to ensure the desired steadiness of support, the cross shears are made of ample length and breadth. On the main carriage is mounted a special hexagonal turret Lathe turret of the hollow type, which is removable to permit of special tool-holders being mounted directly upon the carriage.

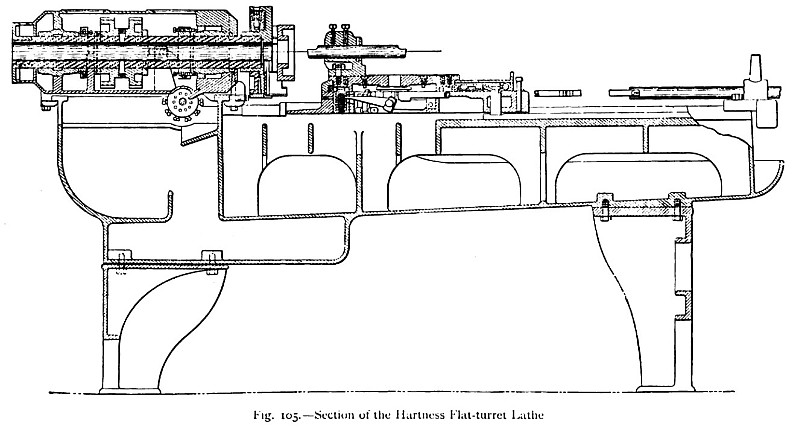

Hartness flat - turret lathes with cross-sliding heads are built in two sizes, each of which is capable of dealing with both bar and chucked work, for which special tool equipments may be obtained. The smaller machine is capable of dealing with bar work up to 21 in. diameter and 24 in. length, and chucked work of 12 in. diameter; while the larger machine deals with bar up to 3 in. in diameter and a length of 36 in., and with chucked work of 14 in. diameter. In fig. 105 is given a sectional elevation of the machine, showing the relative positions of the various parts, which will be described in some detail. From this section it will be seen that the bed of the lathe is cast in one piece with the oil pan and with the oil well under the headstock end, and that in this way the greatest possible rigidity is obtained from the metal used. The bed is supported upon legs at each end, thus rendering special foundations unnecessary. |

|

1911 Jones & Lamson Machine Co., New Flat Turret Lathe

1911 Jones & Lamson Machine Co., New Flat Turret Lathe

1911 Jones & Lamson Machine Co., New Flat Turret Lathe Sectional View

1911 Jones & Lamson Machine Co., New Flat Turret Lathe Sectional View

|

|