|

Title: |

1911 Article-Alfred Herbert, Ltd., Shaving Lathe |

|

Source: |

Machine Tools Commonly Employed In Modern Engineering Workshop, V1, 1911, pg. 90 |

|

Insert Date: |

4/29/2022 9:55:44 PM |

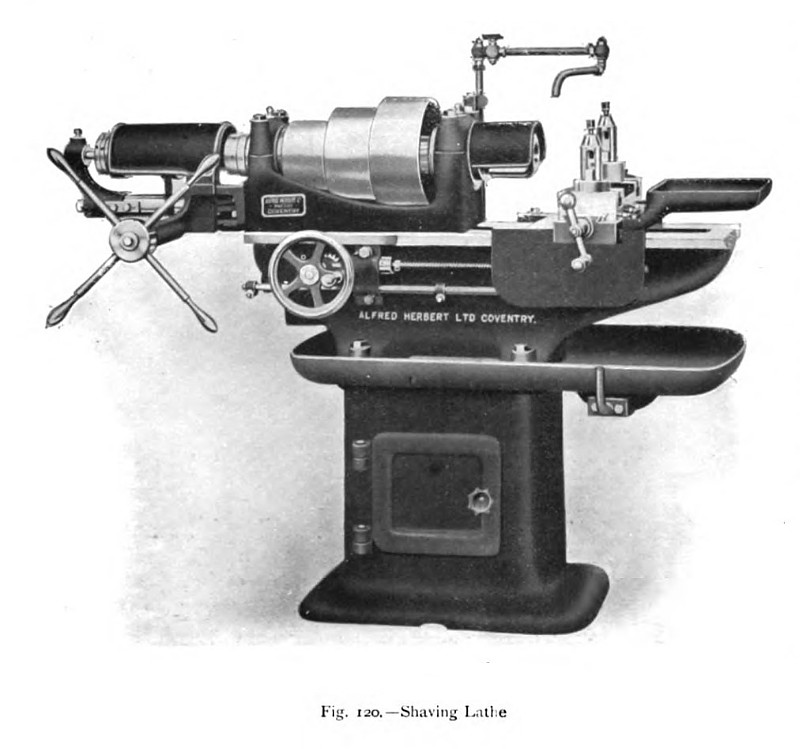

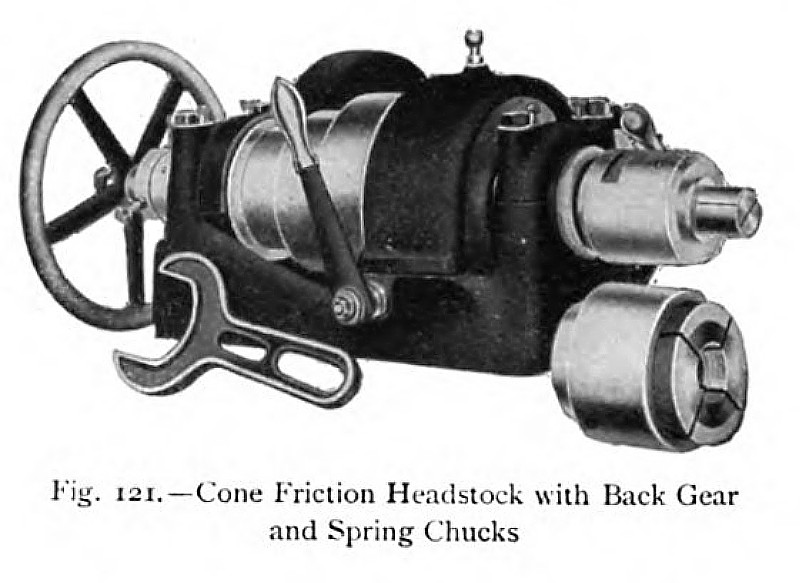

Work produced on the capstan or automatic machine requires to be re-chucked for finishing the end or removing the pip left in the first operation; and, unless a special machine is provided, this involves the use of an expensive machine and skilled labour. When the quantity to be dealt with is considerable, it is advantageous to use a shaving lathe, such as is illustrated in fig. 120, which can be operated satisfactorily by less skilled labour. The head of the machine is driven by a three-step cone pulley, and no back gearing is fitted, as a large range of speeds is unnecessary. For the finishing of the ends of studs and similar work an automatic chuck is provided, as shown in the illustration, the feeding of the pieces and the operation of the chuck being performed automatically without stopping the machine. An ejector is also provided for automatically expelling the piece when finished. Draw-back collet chucks and draw-back arbors are used, according to the nature of the work, and in fig. 121 these chucks are shown as applied to the spindle of a friction-geared type of head. Both chucks, when in use, are operated by the handwheels, shown in the illustrations, in the one case at the end of the spindle, and in the other, fig. 120, at the side of the stock feed gear. The saddle is moved longitudinally by means of a handwheel at the left end of the bed, and automatic stops limit the travel in both directions. A cross slide on the saddle carries two adjustable tool-holders, one at the front and one at the back. In one of these holders can be mounted the shaving tool, and in the other a chamfering tool. By means of screw elevating rings the heights of the two tools can be adjusted to suit the work

When the automatic chuck is in use, the largest diameter of work that can be dealt with is 1 5/8 in., and when the chuck is removed the hollow spindle will accommodate 2-in. bar. If desired, the machine may also be used to deal with chucked work held in suitable chucks, screwed on the nose of the spindle. |

|

1911 Alfred Herbert, Ltd., Shaving Lathe

1911 Alfred Herbert, Ltd., Shaving Lathe

1911 Alfred Herbert, Ltd., Shaving Lathe Cone Friction Headstock with Back Gear & Spring Chucks

1911 Alfred Herbert, Ltd., Shaving Lathe Cone Friction Headstock with Back Gear & Spring Chucks

|

|