|

Title: |

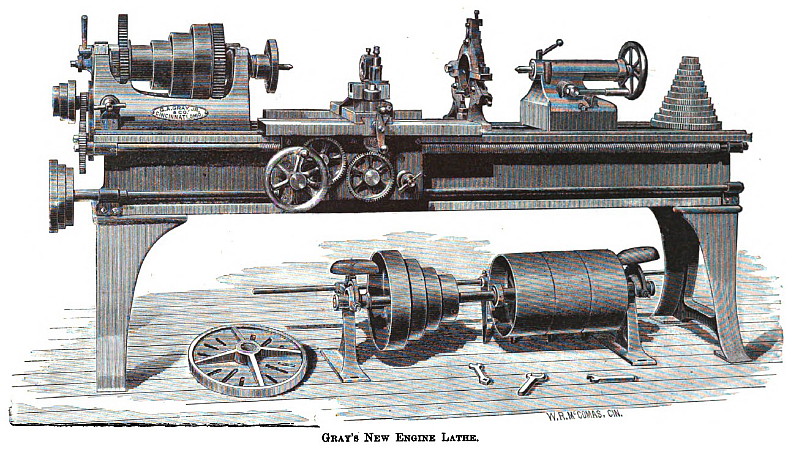

1881 Article-G. A. Gray, Jr. Co.Engine Lathe |

|

Source: |

American Machinist, V4, 24 Sept., 1881 pg 5 |

|

Insert Date: |

3/2/2023 11:17:20 AM |

We present in this issue an illustration of a lathe from the establishment of G. A. Gray, Jr., & Co., Cincinnati. The lathe is a nineteen-inch swing, and is designed on the substantial order, that is, the strength and stiffness of parts is greater than usual, and the power is arranged to be ample for its greatest swing. The spirit of its stiffness may be judged of by the fact that the front spindle bearing is 2¾” in diameter and 4" long. The extraordinary length of carriage bearing will be at once apparent, as will also be the powerful proportions of the cones.

The bed is of extra depth and is in section a strongly tied pair of well-calculated I beams.

Every effort seems to have been made to secure substantial forms free from complication and accessible to a marked degree.

The tool post has an extra broad footing to avoid bruising, and its holder is of the elevating type, having elevating screw compensated for wear, and clamping screw to make all rigid when set. A tilting rest of novel and rigid construction, not dependent on a weight or spring for its stability, is furnished to order instead of the elevating rest shown.

The tail stock is secured by an efficient lever device; and the tail spindle is clamped directly at its end.

The lead screw is set up close under the top flange of the bed and bears against it. This brings the screw very close the line of strain, and prevents that worming of the carriage so often noticed. The screw is entirely protected from falling chips.

The arrangement of the screw gearing is peculiar. Only the gear on the screw is changed for different pitches of thread and the intermediate gear needs no adjustment on the segment.

Upon the change gears is stamped, in unmistakable language, the thread which that gear will produce, thus: “This will cut 8 threads,” “This will cut 12 threads,” etc., etc. The advantages of this arrangement will be at once apparent, and in strong contrast to the usual plan of making an alteration in three or more gears for each different pitch to be cut.

The reverse of the screw or feed is effected by a handle at the head stock; and the reversing mechanism is of such character that the strain of work will never release it, and jar never throw it into action.

The feed is by independent rod, which is thought to be far preferable to the use of the screw as a direct-feeding agent, or to the use of the screw as a driver for a worm-feeding device. The latter plan requires the replacing of proper feed gears after screw cutting, and in many kinds of work where a piece is turned then threaded, then another turned and threaded, and so on, the continual changing of gears consumes a large proportion of the time.

These lathes are built of all sizes; and the material and workmanship is such as to carry out the maker’s intention to put upon the market a tool strictly first class. |

|

1881 G. A. Gray, Jr. Co.Engine Lathe

1881 G. A. Gray, Jr. Co.Engine Lathe

|

|