|

Title: |

1890 Article-John T.Noye Mfg. Co., Rice Automatic Steam Engine |

|

Source: |

The Steam User 1890 pgs 12-15 |

|

Insert Date: |

4/13/2011 3:50:16 PM |

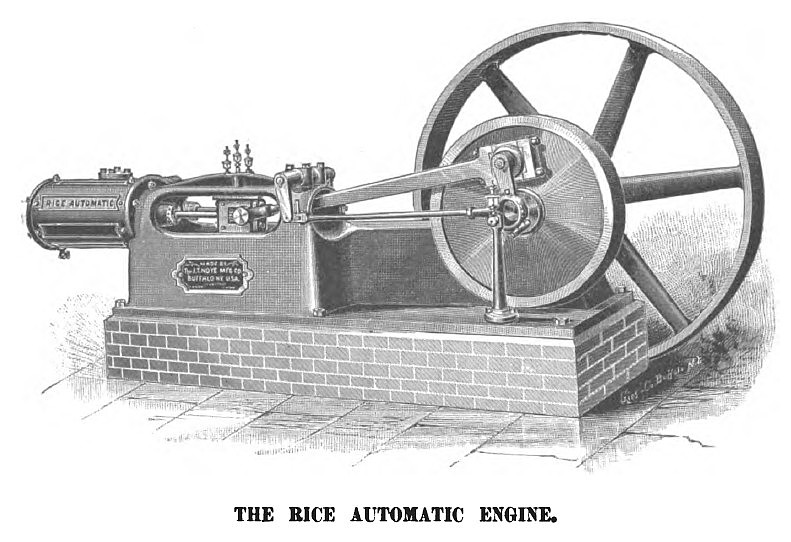

The cut below represents the Rice Automatic Engine, built by the John T. Noye Manufacturing Co., of Buffalo, N. Y. This engine belongs to the latest class of high-speed automatics. It will be seen, however, that the proportion of bore to stroke is somewhat different than most others of this class, so that while the piston speed is about the same, the rotary speed is less. This proportion gives the maximum area of piston with minimum exposed surface, which is, of course, quite an item in economy.

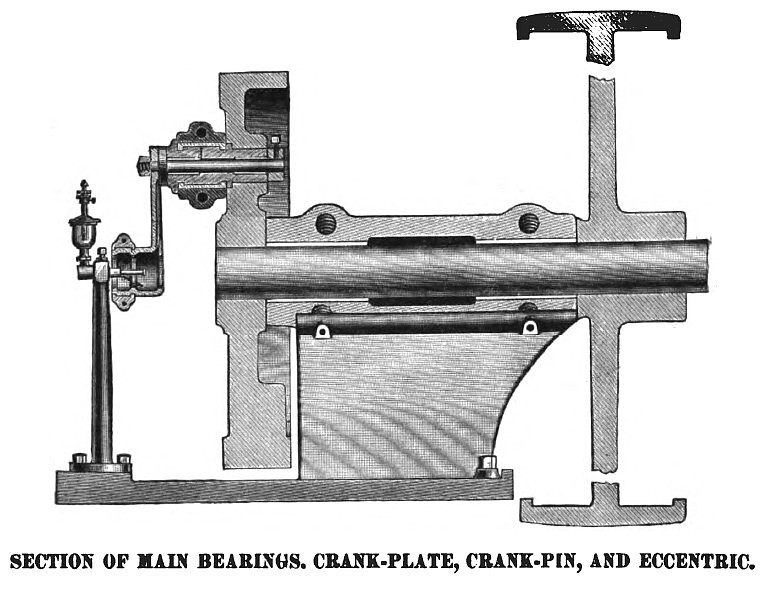

The engine is a novelty in being self-contained, as shown by cross section through the crank shaft. All the working parts are fastened to one solid frame, which is high enough to keep all the parts clear of the floor, and obviates the necessity of a sub base or stone cap. Few side-crank engines can be arranged self-contained without the addition of such sub bases.

As all the parts are left undisturbed after testing, the adjustment is not lost, by shipment; so that when received the engine is ready to operate as soon as the fly-wheel has been keyed on. The sectional view on the next page also illustrates the connection between the eccentric and the governor, which passes through the hollow crank-pin. As will be seen, the crank-pin and eccentric lubrication passes from the stationary oil column through the back of the eccentric to the crank-pin.

Attention is also called to the fact that there are two bearings in the frame, each of which is provided with genuine Babbitt liners cast in iron moulds, so that each one is an exact duplicate of every other one. This renders it extremely easy to renew the bearings in case of need, and that without the danger and delay necessary when hot metal has to be poured around the shaft. The crank-pin is also treated in this manner.

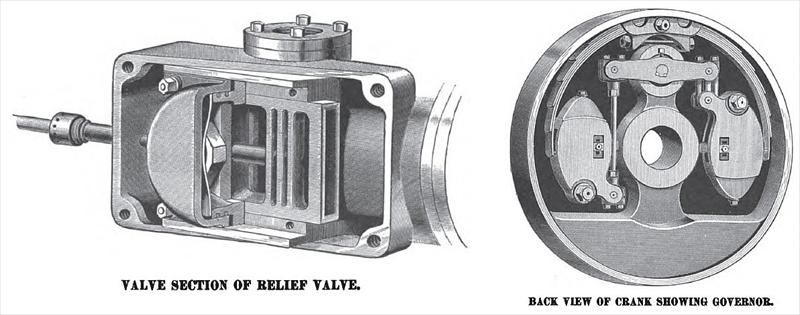

The governor is inside and at the back of the crank, as shown in the cut. It is simple, strong, and well protected from outside accidents. It consists of two balls hung on pivots, and held in equilibrium against centrifugal force by two elliptic springs, whose tension may be increased or diminished by the tension bolt which connects them. The balls are connected to a lever, which, in its turn, is connected to the eccentric through the hollow crank-pin. This is fully shown in the sectional view on the next page.

The balls are cast hollow, and may be loaded with shot, another means of regulation. The governor has no delicate mechanism to get out of order. It can be adjusted to any desired degree of sensitiveness and has complete and perfect control of the entire valve motion.

The valve is balanced from all pressure higher than the exhaust; the steam being admitted from the inside and allowed to nearly surround the entire valve. This gives the governor much greater freedom, and relieves both it and the valve from the wear and tear produced by excessive friction. The valve can be easily operated with one hand upon the smooth valve-stem, when under full pressure of steam.

The relief valve is in the form of a steam-tight piston, which rests on shoulders even with the valve (not on the valve itself), and is kept in place by a steel spring at the back. In case of water or excessive pressure in the cylinder, it allows the valve to raise from its seat, thus avoiding a broken cylinder head or general wreck.

The engine in itself is very complete and compact. The builders are also building the same type of engine in pair and tandem compound condensing form. In this form the engine shows a high rate of economy, having developed a horse-power per hour on less than 1 3-4 lbs. of coal on engines of 100 horse-power.

This company are also building the Rice Automatic Engine in Compound form. There are already a large number of Pair Compounds of this style in use, as well as quite a number of Tandem Compounds of 100 horse-power and under. They are now at work upon patterns and castings for Tandem Compound Engines of a slightly different form, made expressly for heavy duty in connection with Electric Railways and other places where severe strains are sustained; the engine being much lower in the frame and of unusually heavy parts.

The builders will be pleased to furnish all engineers with catalogues and printed matter as well as answer any questions, which they may see, fit to ask. (These engines are manufactured by the John T. Noye Manufacturing Co., Buffalo, N. Y.) |

|

1890 John T. Noye Mfg. Co., Rice Automatic Steam Engine

1890 John T. Noye Mfg. Co., Rice Automatic Steam Engine

1890 John T. Noye Mfg. Co., Rice Automatic Steam Engine (Valve & Governor)

1890 John T. Noye Mfg. Co., Rice Automatic Steam Engine (Valve & Governor)

1890 John T. Noye Mfg. Co., Rice Automatic Steam Engine (Section)

1890 John T. Noye Mfg. Co., Rice Automatic Steam Engine (Section)

|

|