|

Title: |

1896 Article-Gould & Eberhardt, Gear Cutter |

|

Source: |

Cassier's Magazine Sep 1896 pg 339 |

|

Insert Date: |

7/21/2011 4:53:19 PM |

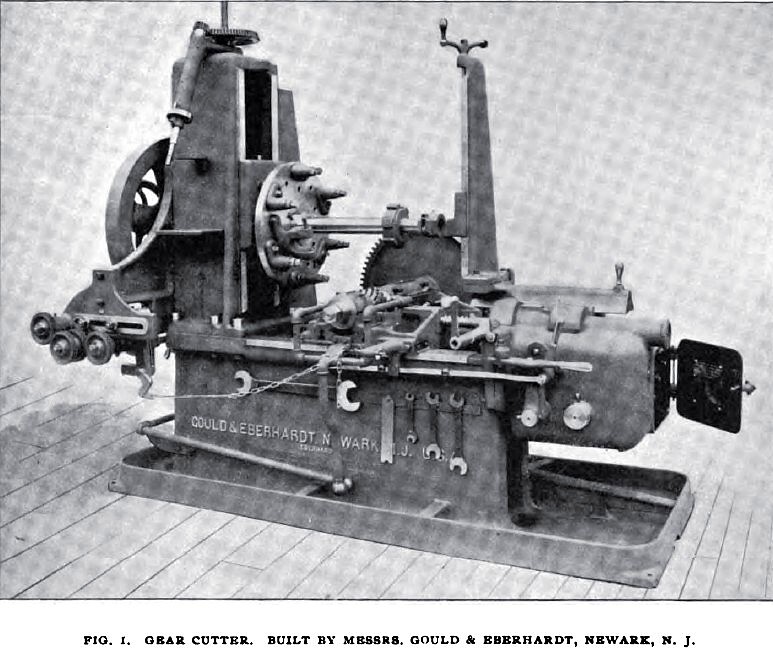

We have an instance of this in the Eberhardt '' New Type '' gear cutter, shown in Fig. 1 on page 339.

The output of this machine will scarcely be believed by those who have not seen it. To the Messrs. Eberhardt belongs the credit of originating the first commercial full automatic gear cutter. Automatic gear cutters had, indeed, been constructed by Sellers, Bement, and others, but their cost was prohibitive. The automatic machine, brought out about twelve years since, was a marked advance over the ordinary gear cutter, because it completed the entire operation of cutting the gear, needing no attention after it had been started.

With the growth of the electric streetcar trolley system, came the demand for a machine which would cut the motor gears in large quantities. The process was slow with any machine of that day, because the pitch is coarse and the material, steel casting, is one of the most trying known to engineers. The " New Type" gear cutter was designed, then, to meet that want, which it does in a marvelous way. Cutting three teeth at a time, it will finish a gear, 23 inches in diameter by 4½-inch face, steel casting, No. 3 pitch (about 1 inch circular), in from 2 to 2½ hours. The length of the cut is 5 5/5 inches, the depth of cut being about ¾-inch, 1½-inch feed to the minute. The cutters are about 5¼ inches in diameter, and the cutting speed is 33 feet per minute. Those who have had experience with steel castings will appreciate what this product means. It will be interesting to make a short analysis of the means taken to reach this result, which is about four times greater than the output of the usual machine. Examining the illustration, we will notice that the massive frame, heavy spindle, and generous wearing surfaces will resist any tendency to deflection and chatter. The spindle is braced by a very stiff end bearing and the gear is firmly held by strong dogs. In addition, six thick streams of lubricant are provided, three playing on the cutters in front and three in the rear, —a perfect deluge. This is a very important point. Of course there is power to spare. Messrs. Gould & Eberhardt use a pang of cutters like that represented in Fig. 2. This shows three finishing cutters, but the cutters stand better if the gang consists of two finishing and two blocking cutters. Of course, the machine is not limited to motor gears. The cutter gang will cut only one size of gear. |

|

1896 Gould & Eberhardt, Gear Cutter

1896 Gould & Eberhardt, Gear Cutter

|

|