|

Title: |

1895 Article-Niles Tool Works, Double Plate Planing Machine |

|

Source: |

Modern Mechanism 1895 pgs 626-627 |

|

Insert Date: |

11/30/2011 9:56:22 PM |

|

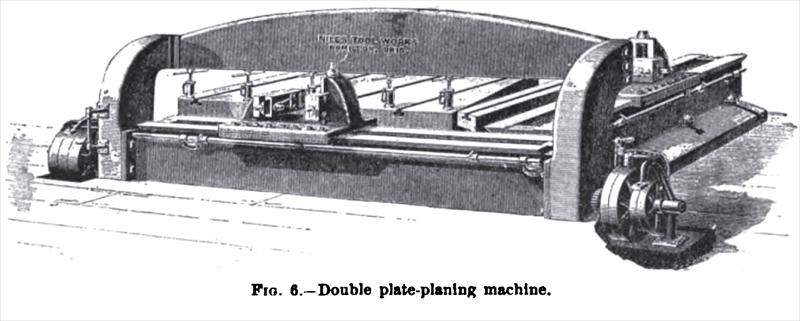

Double Plate-planing Machine — Fig. 6 shows the Niles double plate-planing machine, which is designed to plane on two adjoining edges of plates at the same time. When plates are to be squared or planed to bevel shapes it is of great convenience to be able to do this at one setting of the plate. In the single plate planers, when work is to be planed on the end, the plate must be set by reference to the edge of the table. If the sheet is long and narrow, and is to be planed to any other angle than 90°, the setting becomes a difficult matter if any degree of precision is required. These difficulties are obviated by the use of double plate planers, and at the same time the work is performed both quicker and better. The front or long side, of this machine is similar in construction to the single machines. It has a tool carriage 54 inches long, driven by a heavy steel screw, and carries two tool heads for cutting in both directions. One of these heads has compound and angular movement, as in ordinary planers, while the other has horizontal movement only. The end bed is pivoted at the right hand of the front bed. It is clamped to a heavy T-slotted sole plate, and can be adjusted 10° either way from a right angle by means of a rack and pinion. In this movement the bed carries with it a T-slotted table for holding and clamping the end of the plate. The tool carriage is driven independently in the same manner as the front one. It has one tool head only, with compound and angular adjustment. It cuts in one direction only and has quick return. The clamping bar is a heavy box girder rigidly secured to box housings bolted to the long bed. The housings are overhanging, so that plates of any length may be planed by resetting. The clamping bar is placed at sufficient height to clear the end tool slide, and the work is held by screw jacks. A wide T-slotted table is placed at the back of the machine, suitable for holding large plates without the aid of auxiliary tables. Each tool carriage is driven and operated independently, except that a safety belt-shipping device is provided, by means of which the front tool carriage reverses the motion of the end carriage whenever there is danger of a collision between them. |

|

1895 Niles Tool Works, Double Plate Planing Machine

1895 Niles Tool Works, Double Plate Planing Machine

|

|