|

Title: |

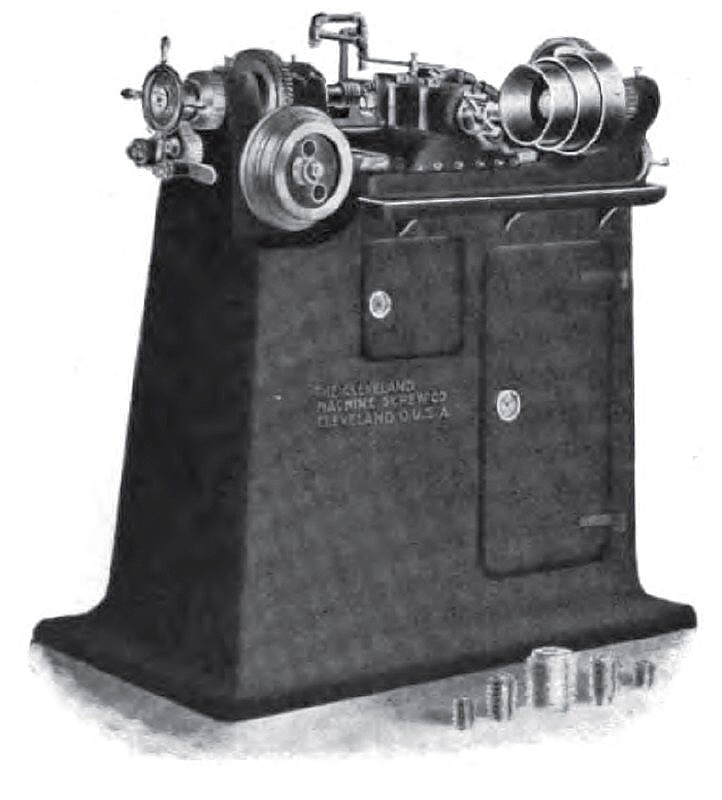

1902 Article-Cleveland Automatic Machine Co., Worm Milling Machine |

|

Source: |

Cassier's Magazine Nov 1902 pg 25 |

|

Insert Date: |

6/25/2012 7:59:03 PM |

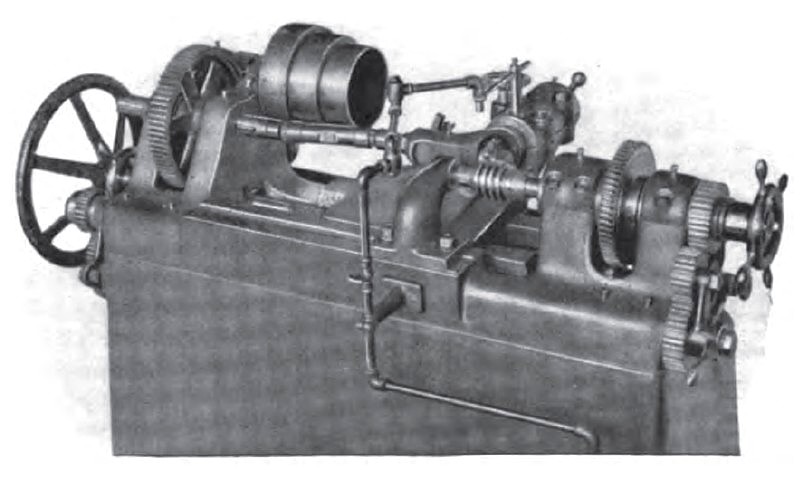

Has the reader ever considered what it costs to chase thread on worms in lathe? If he has not, it would be well worth giving serious consideration, that is, in comparing the output of our worm milling machine against the output of the lathe. This worm milling machine is designed to mill worms, taps, of any pitch, either single, double, triple or quadruple threads, either right or left hand, and its capacity is 4 inches in diameter by 6 inches long. It is well known that milling is the quickest and therefore the most economical method of removing metal, and if there is any question as to the truth of the above statement, the machine here described proves it beyond a doubt by milling worms five to ten times cheaper than what it can be done in a lathe, exact duplicates of one another.

The screw is driven through gearing from the main spindle which carries the worm blank; thus the cutter and blank are always held in proper relation, regardless of pitch of screw or worm to be cut, making it impossible to lose the thread should the cutter be drawn out of work for any reason. The advantage of this point can be made plain by considering the other methods of cutting worms. The cutter resembles an ordinary rack cutter, and there are a great many cases where the same cutter is correct for different threads where at first it would not be apparent; for instance, a cutter for ¼ inch lead single thread is correct also for a ½ inch lead double or 1 inch lead quadruple, etc., the actual size of thread being the same in all. The cutter may be adjusted in or out without disturbing the angle adjustment. A continuous stream of oil flows on cutter and keeps the cutting edge flooded. The movements are identical for triple, quadruple, etc., threads. All adjustments can be made in a few seconds by an inexperienced person. All end thrusts are taken on ball bearings, and all running bearings are bushed. |

|

1902 Article-Cleveland Automatic Machine Co., Worm Milling Machine

1902 Article-Cleveland Automatic Machine Co., Worm Milling Machine

1902 Article-Cleveland Automatic Machine Co., Worm Milling Machine (rear view)

1902 Article-Cleveland Automatic Machine Co., Worm Milling Machine (rear view)

|

|