|

Title: |

1893 Article-C. M. Russell & Co., 4-Valve Automatic High-Speed Steam Engine |

|

Source: |

Cassier's Magazine Jul 1893, pgs. 230-231 |

|

Insert Date: |

11/22/2012 8:47:25 PM |

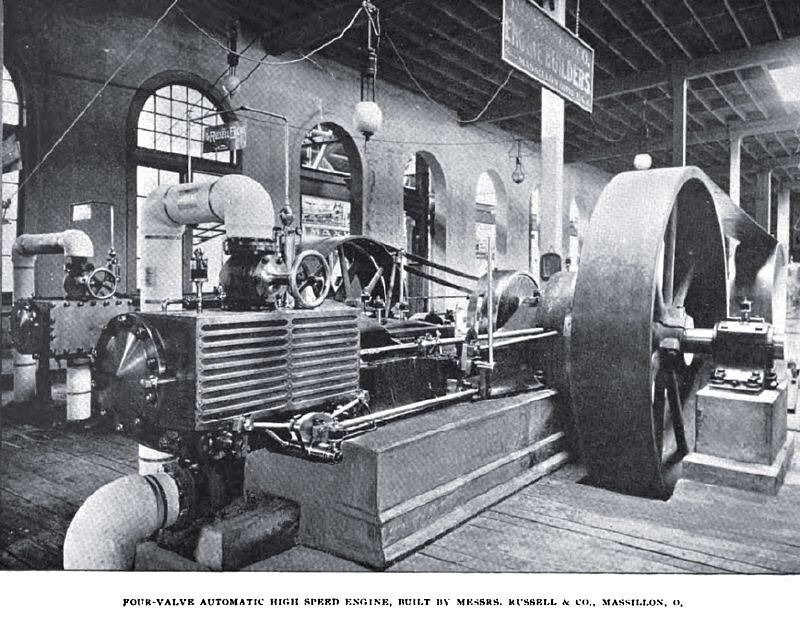

The exhibit of Messrs. Russell & Company, of Massillon, Ohio, comprises six automatic engines. One of these is a double tandem-compound, four-valve engine, measuring 15x24x24 inches, and running at a speed of 125 revolutions per minute. It has a balance wheel measuring 120 by 60 inches, and weighing 36,000 pounds, and the total shipping weight of the two engines complete amounts to 89,172 pounds. The engines will develop 600 horsepower, with a claimed water consumption, accounted for by the indicator, of 14½ pounds per horse-power per hour running non-condensing. The admission and cutoff valves are triple-ported, balanced slide valves, balancing being effected by admitting steam between the valve faces, leaving narrow strips or bridges for the valves to ride on. Actual contact of surfaces is prevented, and the valves are really carried between layers of steam, making their movement a very easy one. The cutoff valves slide on the backs of the main valves, and are operated by a separate eccentric, which is connected to the governor so as to cut-off proportionately to the load. The extreme range of cut-off extends from 0 to ¾ stroke. The cut-off eccentric, as usual in governing arrangements of this kind, fits loosely on the engine shaft and is connected with the weight arms in such a manner that it is moved around the engine shaft, either forward or backward, as the weights change their position, thereby cutting the steam off earlier or later in the stroke as the governor, or more properly the weights, adjust themselves to the load. When the cut-off eccentric is rotated forward, that is around the shaft in the direction the engine runs, the steam is cut off earlier in the stroke; when the eccentric is rotated backward the steam is cut-off later in the stroke.

The exhaust valves are cylindrical in shape and are operated through wrist-plates by the same eccentric that works the main steam valves, but their connection to the wrist-plates is such as to insure a "dwell" at the time of steam admission, and a correspondingly rapid motion at the time of release. This makes the maximum travel of the exhaust valves occur at a time when the pressure upon them is very small and insures smooth working. The whole valve gear, it will be understood, is designed so that the cut-off valves of both high and low-pressure cylinders are under the control of the governor. |

|

1893 C. M. Russell & Co., 4-Valve Automatic High-Speed Steam Engine

1893 C. M. Russell & Co., 4-Valve Automatic High-Speed Steam Engine

|

|