|

Title: |

1895 Article-J. L. Perry Machine Co., Perry Sand-Papering Machine |

|

Source: |

Industry Magazine, Jun 1895, pg. 337 |

|

Insert Date: |

12/12/2012 9:19:27 PM |

It will seem a strange proposition to say that a class of machines now standard or universally employed in the manufacture of joiner work at the East, are unknown on this Coast, unless it be in some of the principal door and sash factories, and we have been informed they are not in use even there.

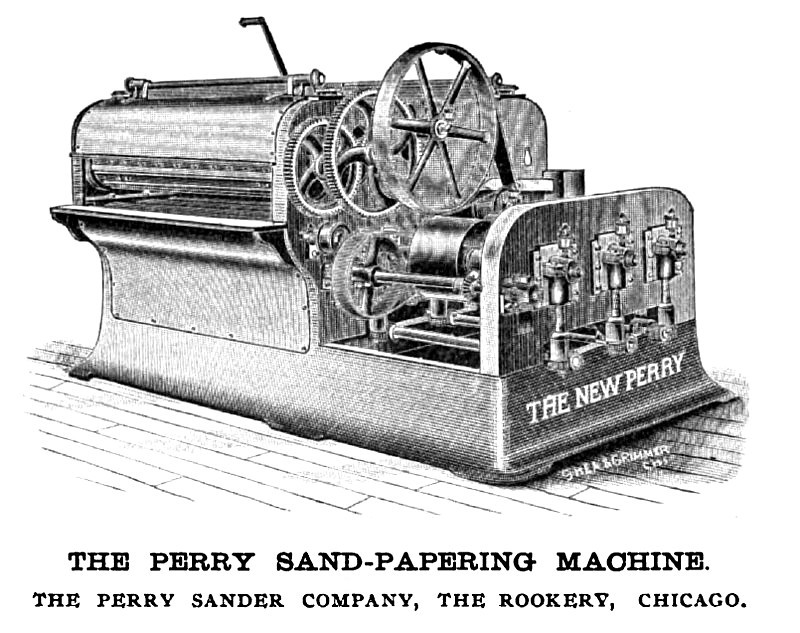

Before speaking of the effect or purpose of the machines, of which one of the latest is shown in the drawing, we will point out the inevitable path of "evolution" they have come through.

The application of sand paper by machines is an American invention that depended at first to a great extent upon the production of suitable web paper for this purpose, a problem worked out mainly by Messrs. Baeder & Adamson, of Philadelphia, Pa. The covering or abrasive surface is, or was some years ago, a fine flint stone procured in Nova Scotia, which was found superior to glass, commonly used for like purposes in Europe. The web itself required strength almost equal to cloth, and the adhesive glue had to stand a good deal of heat as well as moisture, unavoidable at times in the Eastern climate, but the problem was finally worked out, and paper of all grades of fineness was made to stand use on drums when the drums were properly made.

The machines have been in "evolution" about twenty years, all the time rising in quality, efficiency and price, until at the present time there seems to be nothing more to do in improving them.

The stuff, that is all flat surfaces to be painted or varnished, is put through the machine at a cost that aside from the wear of the paper is hardly considerable, and the result a perfect surface irrespective of grain or texture of the wood. The greatest effect economically is in " cleaning of sash doors and other framed work where the grain is crossed, or at right angles. The company at Chicago semi the following description of the Perry machine shown in the drawing: " The new "Perry" is a triple—drum endless-feed belt sander. The three drains are made of steel and iron. and can be contracted and expanded when the sand paper is renewed. The circumference of the cylinder is covered with the very best of packing, which is varied according to the work to be done. As usual in triple-drum sanders the paper may be graded. the ?rst cylinder having coarse paper and the other finer. The distinctive feature of our drums is that they ca|1 be contracted and expanded. Besides this the dr1.1n:|s have at one end a removable bearing. The purpose of the removable bearing is, ?rst, to make the change of paper easy and quick; and second, to remove the cylinder itself if necessary. The paper is formed into a hollow cylinder, and tightly clamped by our patent fastener, then with the end bearing removed, and the drum contracted, this hollow cylinder of paper is slipped on over the drum into place, the drum is expanded and the bearing replaced. In this operation there is no loss of adjustment either of the cylinder or feed, and much less time is taken to change the paper than with any other previous construction. The drums can be adjusted independently of each other according to the cut desired. Above the drums in place of the ordinary rigid metallic feed rolls used on all other sanders is the rubber-faced endless belt. The endless feed belt consists of twenty-nine parallel slats linked together at the ends, and passing‘ over sprocket wheels at the ends of sander. These metal slats have mortised into them, and held in place by a steel band, heavy rubber strips. The metal slats in the feed belt are held rigidly against the stock by two or three pressure bars, so that any stock which might he warped is held evenly and tightly down against the cylinders and lower bed. The rubber faces have, ?rst, a firm hold on the stock, and there is no danger of stalling; second. they have a continuous hold, so that the stock is never once released from the time it enters the machine until it leaves the last polishing cylinder; third, it will carry through short stock not more than four inches in length, one piece at a time, or as many together as the width of the machine will allow; fourth, it will pass through stock varying slightly in thickness, as, for example. hard-wood flooring, and, fifth, if any dust sticks to the rubber it will not print the stock, a very common and unavoidable fault with feed-roll machines. Another feature of the construction is that all of the pulleys and the few gear wheels are enclosed within the machine, and the shafts of the cylinders have three bearings. The illustration shows practically all the gearing there is on the machine. The feed belt does away entirely with the thirty or more gear wheels used in other machines to propel feed rolls. The feed and oscillation are driven by a short belt taking its power from the cylinder shaft, and the entire machine is thus driven from a single pulley on a short countershaft. As the endless feed belt is driven from the cylinder shaft there is no danger of the feed belt stopping unless the cylinders stop also. consequently the stock cannot stop over the cylinders when the latter are in motion; however, by a very simple device the feed can be stopped instantly without stopping the cylinders." |

|

1895 J. L. Perry Machine Co., Perry Sand-Papering Machine

1895 J. L. Perry Machine Co., Perry Sand-Papering Machine

|

|