|

Title: |

1895 Article-Bentel, Margedant & Co., Machine for Boring Wooden Tubes |

|

Source: |

Industry Magazine, Dec 1895, pg. 724 |

|

Insert Date: |

12/13/2012 10:32:37 PM |

|

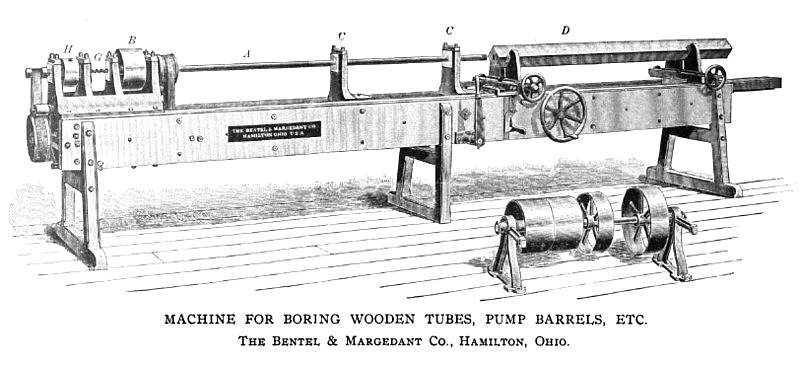

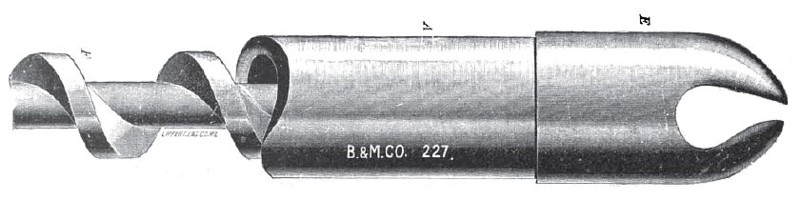

How long tubes of Wood are bored, is a puzzle to most people as great as the problem to King Charles of "how the apple got into the dumping", and is especially a matter of interest on this coast, judging by the inquiries that have been received at this office during the last eight years Having ascertained that the Bentel & Margedant Company made a specialty of machines of this kind, we applied for information which has courteously been supplied, and will be published here and in our next issue. Beginning with the boring process which may be called the base of the system. The machine shown on the page opposite is one for plain boring holes up to 4 inches diameter, and of any required length, the drawing representing a machine for boring wooden pump barrels eight to ten feet long. On this page are shown enlarged drawings of the cutting and clearing implements, so the whole operation can be made quite clear. The main frames are made of "dry wood "glued up," as it is called, from boards to prevent warping. These frames are about two and a half times as long as the stocks to be bored, and could not well be made of metal. On the top are fastened planed ways on which slide the chucks that hold the timber D, the rests C C or other moving parts The boring barrel A is a thin metal tube, turned true, driven by the pulley B. On the forward or cutting end there is fastened a cutter E shown above, having a bore the same as the tube, the shavings or chips passing inward, through the cutter of the barrel A and filling its bore is a helix F, that withdraws the chips through the barrel so they will fall out at G, Fig. 1. The helix or screw F is milled out from solid steel, quite smooth. and is an expensive element of the machine. This screw is driven by the pulley H at a much higher rate than the barrel A, in the opposite direction. The operation of the machine is automatic, that is, the stock D is moved forward by feed gearing operated by the belt and pulley seen at the end of the machine. The truth of the work depends on the correct alignment of all the parts, which in a machine of this length requires careful construction. A machine as shown, to bore eight feet long, costs $460.00, which seems a low price. |

|

1895 Bentel, Margedant & Co., Machine for Boring Wooden Tubes, Pump Barrels, Etc.

1895 Bentel, Margedant & Co., Machine for Boring Wooden Tubes, Pump Barrels, Etc.

1895 Bentel, Margedant & Co., Tool Bit for Boring Wooden Tubes

1895 Bentel, Margedant & Co., Tool Bit for Boring Wooden Tubes

|

|