|

Title: |

1900 Article-Alfred Herbert Ltd., Chasing-Saddle Turret Lathe |

|

Source: |

English & American Lathes, 1900 pg 128 |

|

Insert Date: |

12/20/2012 12:15:32 PM |

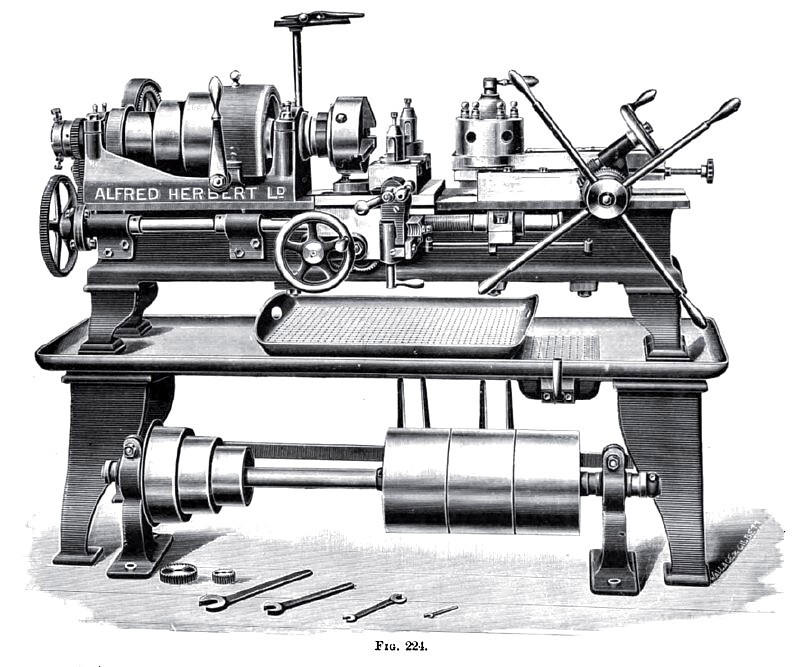

Fig. 224 illustrates one of A. Herbert's patent chasing-saddle turret-lathes. It is designed to do the work of those types of turret-lathes in which screws are cut by means of a chasing-bar and leaders, or master-screws, the best known type of which is the Fox. Here the chasing-bar is abandoned, the saddle taking its place, and the leaders are placed on a feed-rod in front of the bed, geared from the headstock spindle; leaders of different pitches can be substituted, and fulfil the purpose of lead-screws for cutting short threads of other pitches by changes of gear in a swing-plate. A handle, seen at the lower edge of the saddle, operates the clasp-nut, and acts as a quick-withdrawal to the tool. One movement, therefore, of this handle withdraws the nut from the leader, and the tool from the work, and a movement in the opposite direction puts the nut into gear with the leader, and returns the tool into the correct position for cutting. The operation is, therefore, as handy as that of the ordinary chasing-bar, while the threads are cut as accurately and firmly as those which are produced in a screw-cutting lathe. By using a leader of fine pitch the saddle can be traversed for fine turning-feeds. The saddle also can be utilized as a compound rest. The capacity is large, taking bars up to 2 in. diameter. It is made for back-gear or single-gear, with or without automatic opening and closing chuck, taking, in the latter case, bars up to 1½ in. diameter. The illustration shows the lever by which the friction-clutch which operates the back-gear is thrown in and out. In this, as one example, the bottom bracket axle of a bicycle can be made from the bar, the projecting end being first turned to size by the capstan tools, and then sustained by a supporting bush. The superfluous metal is then roughly removed by a turning-tool at the back of the rest, and a formed tool at the front of the rest is fed into the work, taking off a cut the full width, and, of course, reproducing exactly the outline required. The piece is finally severed by a cutting-off tool.

A special tool for turning taper articles from the bar can be applied to any of the regular capstan-lathes. In making a taper bicycle-pin, the taper tool consists of a pair of rocking-levers, carrying cutters at their lower end. A forming bar is fitted between these levers at the upper end, which, when the capstan is moved forward, comes into contact with an adjustable bar, which prevents its further forward movement. The capstan being then moved forward, the rocking-levers slide along the forming-bar, which opens or closes them, reproducing accurately the taper or curved outline required. The threading, finishing of the end, cutting off, etc., are done by ordinary capstan tools. |

|

1900 Alfred Herbert Ltd., Chasing-Saddle Turret Lathe

1900 Alfred Herbert Ltd., Chasing-Saddle Turret Lathe

|

|