|

Title: |

1902 Article-J. E. H. Andrew & Co., Bisschop Gas Engine |

|

Source: |

Gas & Petroleum Engines, 1902, pg. 74 |

|

Insert Date: |

9/11/2013 9:46:01 PM |

Bisschop Engine

Alexis De Bisschop, in 1870, 1872, and 1874, patented and constructed for purposes requiring only very small power an extremely useful and handy little gas engine of the vertical non-compression and direct-acting atmospheric type.

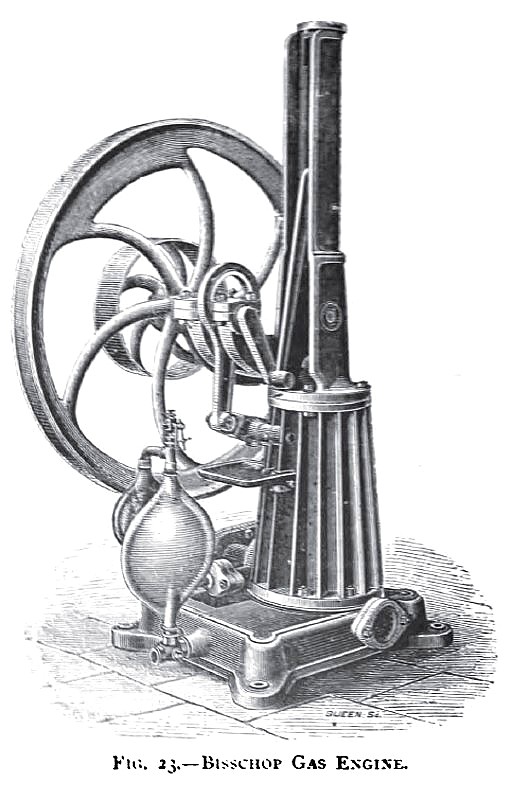

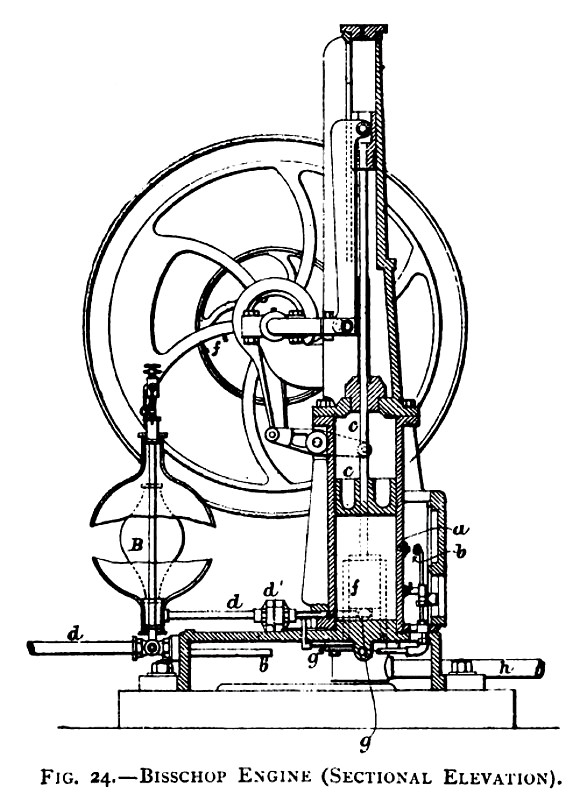

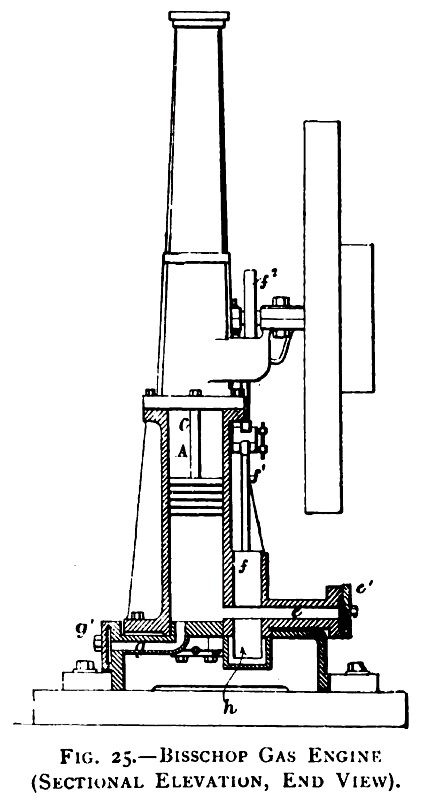

Fig. 23 gives a view, and Figs. 24 and 25 sectional elevations of the BISSCHOP engine, as improved by Messrs. Andrew, of Stockport, the English makers.

A long rod connects the crank on the driving-shaft with the cross-head of the piston rod, which is guided in the open hollow column above the cylinder. When the explosion takes place, this long connecting rod and piston rod are almost parallel, so that the piston then gets a direct pull at the crank without any side pressure on the guide and piston.

A cylindric piston valve f, Fig. 24, communicates with the lower part of the cylinder and controls the admission and distribution of the charge and the exhaust of the burnt products. It is worked by a rocking lever f1, and eccentric f2, fixed on the driving-shaft. There are two gas jets, Fig. 24; one b shoots a flame through a hole a in the wall of the cylinder, the other is placed beneath to re-light b.

The engine is fed from two india-rubber bags B, which serve as reservoir and regulator for the gas supply to keep the engine at the proper speed. There is no governor. The gas admission valve d consists of a thin iron disk, having holes covered with a circular sheet of india-rubber, which is sucked away from the disk, and allows gas to enter when pressure in cylinder is less than that outside. Similarly the air valve e (Fig. 25) is opened by the air pressure outside, and closed by the explosion inside the cylinder. Andrew adds an extra air valve by which cold air is drawn in at the commencement of the up stroke to mix with and cool the residual products in the ports. This effects a saving in gas consumption.

No water-jacket is required, as the engine is kept cool by a number of radial flanges or brackets in the casting round the cylinder, which present a large cooling surface to the atmosphere, and give stability to the structure.

As the piston is raised, it draws in a mixture of gas and air at atmospheric pressure; at about one-third of its up stroke the piston uncovers the lighting port (closed by a steel clack), the flame is sucked into the cylinder and fires the charge; and the piston is driven up rapidly to the end of its stroke. The energy thus stored up in the fly-wheel carries the piston through the down stroke, driving out the burnt products by the exhaust pipe h, and one-third of the way up again drawing in a fresh charge. The indicator diagram is similar to that of the Lenoir and Hugon engines. The Bisschop is adapted only for very small powers, one, two and four man-power (half-horse-power), being the usual sizes. Its great merit lies in the simplicity of its parts, and practically no oil is required except for the bearings. In most other gas engines oil is a very large item in the working expenses, hence the Bisschop works more economically than indicated by the gas consumption, which is at the rate of about 130 cubic feet of coal gas. per brake horse-power per hour. The two man or ¼ horse-power, consumes 30 cubic feet per hour, and the four man or ½ horse-power, 60 to 65 feet per hour. It does not claim economy of gas when compared with larger modern engines. It occupies small space, requires no water, and its great convenience is to replace manual labour where simplicity and ease in handling arc wanted. Hence it is suitable for small industries, and having been found reliable in action is extensively in use.

Messrs. J. E. H. Andrew and Co., Limited, of Stockport, have never ceased to manufacture the "Bisschop" engine since 1878. They are making it at the present day. Surely this is a case of the survival of the fittest!

See complete article here;

http://www.vintagemachinery.org/pubs/detail.aspx?id=6130 |

|

1902 J. E. H. Andrew & Co., Bisschop Gas Engine

1902 J. E. H. Andrew & Co., Bisschop Gas Engine

1902 J. E. H. Andrew & Co., Bisschop Gas Engine (Sectional Elevation)

1902 J. E. H. Andrew & Co., Bisschop Gas Engine (Sectional Elevation)

1902 J. E. H. Andrew & Co., Bisschop Gas Engine (Sectional Elevation, End View)

1902 J. E. H. Andrew & Co., Bisschop Gas Engine (Sectional Elevation, End View)

|

|