|

Title: |

1905 Article-Tangyes Ltd., Horizontal Gas Engine |

|

Source: |

A Textbook on Gas, Oil & Air Engines, 1905, pg. 101 |

|

Insert Date: |

9/11/2023 2:25:24 PM |

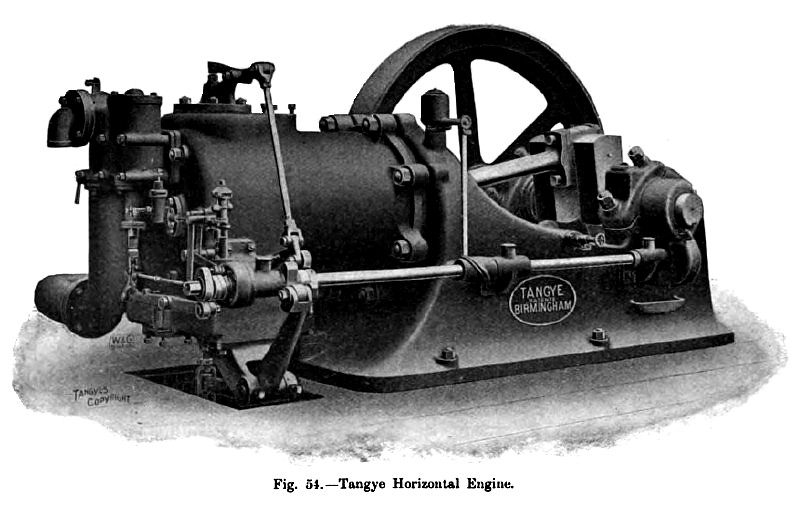

Tangye.—This important firm have ceased to construct the engine described at p. 58 (Robson's patent), and since 1891 have made engines only on the Otto four-cycle principle, with Pinkney's improvements. Next to Messrs. Crossley they at present build some of the largest motors in England. Their single-cylinder horizontal engines range from 2½ to 340 B.H.P. with lighting gas, and the maximum piston speed in them is 750 feet per minute. The smaller sizes have no timing valve, punctual ignition being obtained by adjusting the chimney of the tube. In the larger horizontal engines porcelain tube igniters are used. The combustion chamber is carefully constructed to prevent shock, and render the engine suitable for driving a dynamo direct, and also to ensure steady and complete combustion of the charge during the whole of the motor stroke. The cylinder casing, combustion chamber, and exhaust valve-box are all made in one casting.

Messrs. Tangye have lately introduced a new vertical type, especially adapted for driving dynamos, with two or three cylinders, developing from 32 to 340 B.H.P. with town gas, and 27 to 320 B.H.P. with producer gas. The speed is about 250 revolutions per minute. The charge is fired by a small magneto-electric machine. As there is an explosion in each cylinder every second revolution the crank receives a motor impulse at each two-thirds of a revolution, and increased steadiness in running is thus obtained. Compression in the Tangye engine is kept within moderate limits; in a trial by Professor Witz of a 26 B.H.P. engine, details of which will be found in the Tables, the mean pressure at ordinary load was about 84 lbs., and at maximum load 97 lbs. per square inch. The smaller engines are started by hand, in the larger a low-pressure starter is used, and a charge of gas and air sent by a small hand pump into the cylinder. For powers above 80 H.P. the engines are started by compressed air from a reservoir charged either by a small starting engine, or the main engine. Governing is on the "hit-and-miss" principle in the horizontal engines, a sensitive centrifugal governor being used. By an ingenious arrangement the next impulse after a missed explosion is stronger than usual. When the governor cuts out the supply of gas, the air, which alone enters the cylinder, drives out the products of combustion. The governor then moves up a small wedge, opening the gas valve more than before, and a specially rich charge is obtained. In the vertical type the governor on the flywheel acts by throttling the admission valve, and varies the quantity of the charge admitted, the proportions of gas and air remaining the same. Both the compression pressure and the strength of the impulse are thus reduced according to the load. The lubricating oil is contained in a receiver in the base, into which the end of the connecting-rod dips, and throws the oil over the working parts. |

|

1905 Tangyes Ltd., Horizontal Gas Engine

1905 Tangyes Ltd., Horizontal Gas Engine

|

|