|

Title: |

1895 Article-H. W. Ward & Co., Lincoln Miller & Drill Press |

|

Source: |

Engineering Magazine, V 59, 19 Apr 1895 pg. 601 |

|

Insert Date: |

11/3/2013 1:22:08 PM |

DOUBLE-GEARED DRILLING AND

MILLING MACHINES.

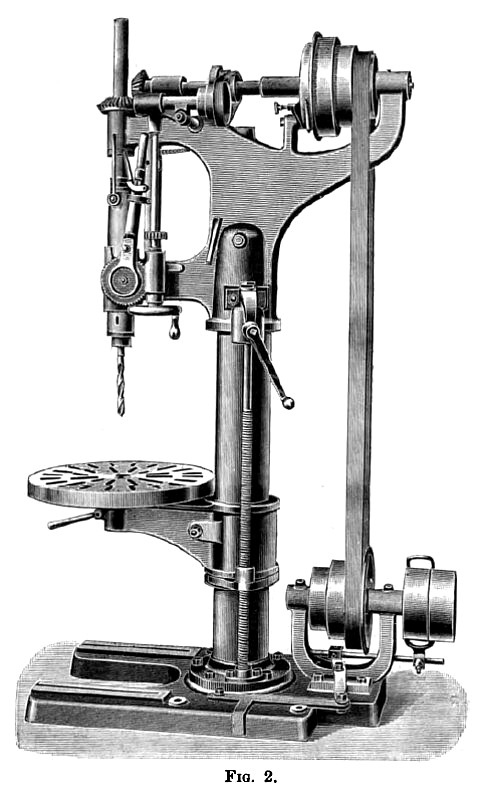

We illustrate on page 601 two excellently designed machines recently introduced by Messrs. H. W. Ward and Co., of the Tudor Works, Ladywood road, Birmingham. The double-geared drilling machine shown in Fig. 1 is fitted with a number of special motions. Thus there are four methods of feeding the spindle, all of which come in useful for particular classes of work. By means of the lever and ratchet, working on the worm-wheel shown to the front of the machine, a rapid feed can be given in doing light work. The spindle can also be fed by a short quick-withdrawal lever, not shown in the illustration, by the ordinary worm gear and handwheel, and finally, by an automatic feed, which is fitted with a throw off gear, to stop the feed at any desired point. The spindle has a long parallel bearing, and is fitted with balls top and bottom to take the thrust. These balls run in hardened and ground races of special form, by means of which such small wear as occurs may be compensated for. The double gear is balanced, and is placed inside the driving cone. It consists of an internal wheel, connected with the driving pinions on the cone by means of intermediate pinions carried on a strong frame keyed to the shaft. When the gear is in use, a simple lever fixes the internal wheel, which acts as an abutment to the intermediate pinions, thus giving motion to the driving shaft. When the locking lever is withdrawn, the internal wheel and cone revolve together as one. All gears have cut teeth. Work 24 in. in diameter and 2 ft. 5 in. high can be taken under the spindle. The table and bracket are very massive. The machine, it will be seen, is entirely self-contained, the fast and loose pulleys and driving cone being fitted on an extension of the bed-plate below.

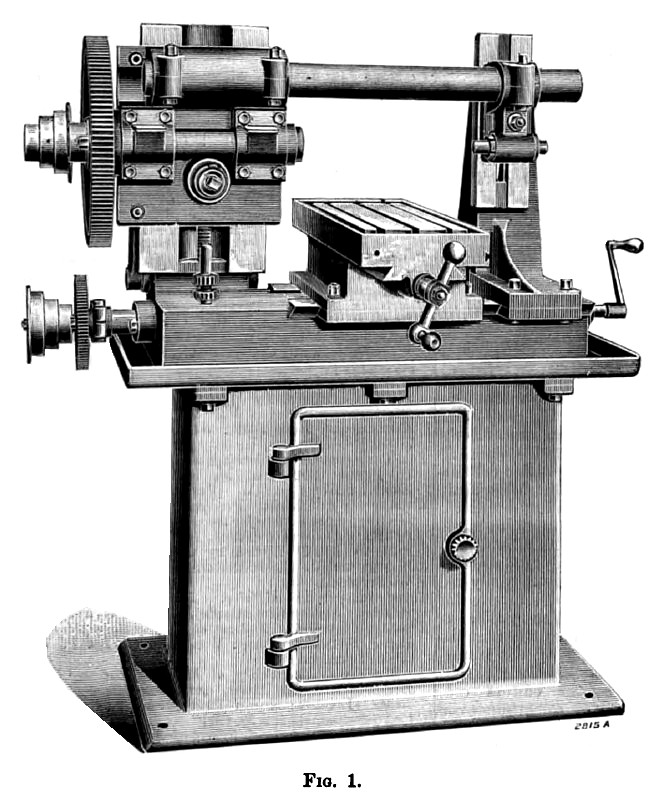

The second machine is a double geared milling machine, which is made in various sizes, that illustrated having a table 20 in. long and 7½ in. wide This table is fitted with an automatic traverse, so arranged that hand motion can be used at the same time and without throwing the self-acting motion out of gear. It can be adjusted 6 in. longitudinally. As will be seen, the base is very substantial, giving the machine the rigidity which is essential to satisfactory working Being of the box type, it is fitted with a door, and serves as a cupboard for keeping the cutters, tools, &c. A soap trough is supplied at the top. The spindle is hollow, and is fitted on a rising and falling saddle, which can be adjusted to a nicety, and is provided with a registering dial. The steady bar which carries the back centre is supported at one end by this saddle and at the other by a bracket bolted to the bed of the machine. It can, however, be readily removed when it is desired to mill an overhanging piece of work. Owing to this provision, the spindle is very solidly supported, Bo that very heavy cuts can be taken. The machine will pass 18 in. between the head and the steady bracket. The spindle has a vertical adjustment of 6 in., being, when at its lowest point, 2 in. from table to centre, and consequently 8 in. when at its highest point. The round steady bar and back centre can be used without the vertical bracket, and the machine generally, and, in conjunction with various attachments, is capable of a great variety of work. All the gearing is machine cut from the solid, and the spindle ground and hardened The London representative of the makers is Mr. E. C. Amos, M.I.M.E., 11, Queen Victoria-street, E.C

Note: The description of the second machine does not match the illustration. |

|

1895 H. W. Ward & Co., Lincoln Miller

1895 H. W. Ward & Co., Lincoln Miller

1895 H. W. Ward & Co., Drill Press

1895 H. W. Ward & Co., Drill Press

|

|