|

Title: |

1908 Article-Frick Co., "Eclipse" Steam Traction Engine |

|

Source: |

The Traction Engine, Its Use and Abuse, 1908, pgs. 131-135 |

|

Insert Date: |

3/22/2014 8:09:04 PM |

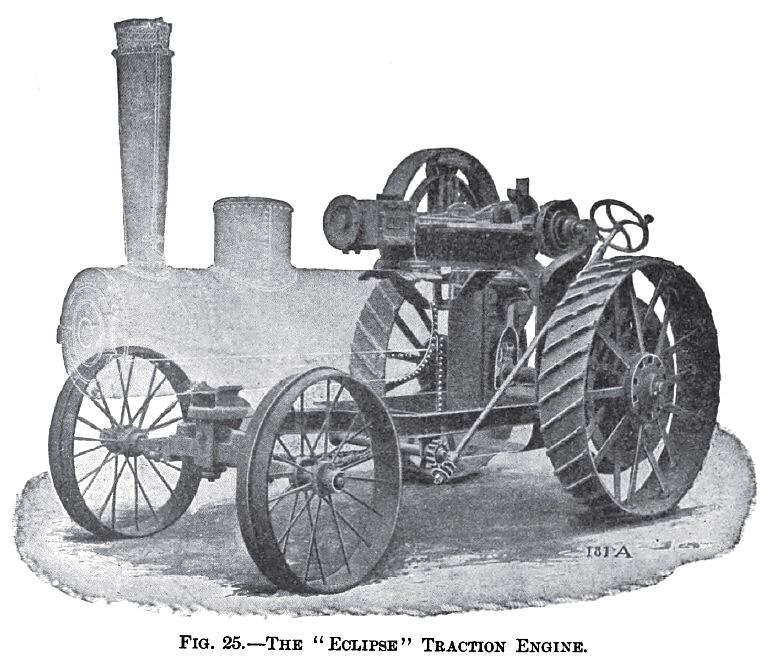

THE "ECLIPSE" TRACTION ENGINE.

In this engine, manufactured by the Frick Co., a separate steel frame has been provided for the support of the driving wheels, the front wheels, the engine, etc., and on this frame rests also the boiler, supported on sliding joints. By this arrangement the boiler is relieved not only of all outside strains due to the mounting of the machinery directly on the boiler shell, but also of internal strains due to the expansion or contraction of its various parts.

The boiler, of the regular locomotive type, is provided with a large fire-box and an ample supply of tubes. The crown-sheet is so arranged that it is well under the surface of the water whether the engine is going up a steep grade or going down.

The smokestack is located in the front, and is provided with a cone-shaped screen for spark arrester. A cross-head pump and a Penberthy injector are used. The water-tanks, one on each side of the boiler, are supported directly on the steel frame and located in front of the driving-wheel.

The engine, of the center crank type, is placed on top of the boiler. It is independently supported on a steel frame spanning the boiler and fire-box and riveted to the side of the main frame. The cylinder end rests loosely on the shell of the boiler. Cylinder, bed-plate, crosshead, and slides are made of cast-iron; and cross-head gibs, crank-shaft bearings, check-valves and connectingrod boxes are gun metal. The gears are all cast-iron. Steel is used for the main axle, the countershaft, the crank shaft, the piston rod, the pump plunger and the valve stems.

The power is transmitted from the engine to the main axle by means of a direct train of gears in which is included a compensating gear. The compensating gear is so arranged that by pulling on a lever the two driving wheels are locked together. It is hardly necessary to point out the value of this device when pulling out of a bad place.

The connection between the main gears and the driving wheels is accomplished by means of four spiral steel springs in order to prevent as much as possible any sudden blows on gears and shafts.

In place of the usual locomotive links a special reversing gear is used. It is of a simple construction and contains very few parts.

Most of the wearing parts are encased in dust-free covers, and provided with self-oiling devices. The cylinder is oiled by a sight-feed lubricator.

The steering chains operated by the steering wheel and a worm gear are attached to the front axle by means of spiral steel springs. This way of attaching the chains allows the front axle to move a little when a small obstacle in the road is encountered, but compels it to resume its original position as soon as the obstacle has been passed. It also prevents a great deal of vibration.

The brake is applied directly on the main axle and is of the steel band type. The fly-wheel is provided with a friction clutch and the location is such that the belt can be run to the front as well as to the rear of the machine. The engineer's platform is mounted on springs. Steering wheel brake, reversing gear, throttle valve, whistle, pump, injector, blower, water-gauge, friction clutch, dampers, etc., can all be reached from this place.

The traction wheels' spokes are made of rolled steel and riveted to the rim. Holes are provided in the rim for insertion of special spurs in order to prevent slipping on frozen roads, or can be used for the attachment of special large mud cleats in case such should be wanted. |

|

1908 Frick Co., "Eclipse" Steam Traction Engine

1908 Frick Co., "Eclipse" Steam Traction Engine

|

|